A new take on sonocrystallization is showing industrial promise thanks to experimental investigations at Diamond Light Source, the UK’s national synchrotron research facility. Joe McEntee reports

Curiosity-driven research using low-power ultrasound fields to investigate the fundamental physics of crystal nucleation – the formation of crystal nuclei and “embryos” in the liquid or solution phase prior to macroscopic crystal growth – is opening a pathway to new, industrially significant methods of process control for crystallization.

Although it’s still relatively early days, scientists from the University of Leeds, UK, are confident their experimental and theoretical insights will ultimately translate into downstream process-equipment innovation. The end game: at-scale commercial opportunities to realize less-energy-intensive modes of materials production – as well as enhanced quality control – across industries as diverse as food manufacturing, pharmaceuticals, agrochemicals, polymer extrusion and personal care products.

The specialist programme on so-called “insonification” is headed up by Megan Povey, professor of food physics at Leeds, who has built an international reputation in the application of ultrasound spectroscopy for food characterization and ultrasound processing in food manufacturing. More widely, her team’s priorities span computer and mathematical modelling of foods; commercially deployable sensors and instrumentation for safer foodstuffs; and novel process technologies for sustainable production. All of that built on a solid fundamental understanding of materials properties, structure and behaviour.

Unpacking the fundamentals of food

Povey’s latest scientific endeavour is true to those core research themes. On the one hand, her team is developing granular mathematical-physical models – based on the rectification of heat and mass transport – to understand how low-power ultrasound influences the behaviour of a wide range of nucleating systems. “Everything I do in food physics, I need a theoretical underpinning – a model – before moving onto the experimental aspects,” Povey explains. “After all, empiricists need more than empiricism. They need physical models they can iterate and optimize with real-world experimental data.”

Along a parallel coordinate, Povey and colleagues are pursuing an experimental line of enquiry that relies on low-power ultrasound to control crystal nucleation – in effect, the insonification of a solution or liquid without inducing cavitation (i.e. formation of small vapour-filled bubbles or voids that can collapse and generate shock waves within the fluid medium). In this context, low power is defined by a mechanical index (MI) of 0.08 or less, a measure of the maximum amplitude of the ultrasonic pressure pulse (and sufficiently low as to minimize the likelihood of cavitation).

“By controlling the ultrasound frequency, power and duration according to the nature of the crystallizing material, we have shown that it is possible to promote or suppress crystal formation,” notes Povey. “Equally, the level of control we see is much more granular and extends to the rates of nucleation and crystallization as well as the numbers, sizes, geometries [habits] and morphology of the crystals in emergent networks.”

The upsides for industry, she thinks, could be game-changing. “Think faster nucleation and uniform nucleation throughout the sonicated volume as well as the generation of smaller, purer and more uniform crystals.” A case in point is the production of pharmaceutical “actives”, where control of polymorph (a single chemical species that can exist in different crystal structures that may change their chemical and physical properties) is often crucial. “The dreadful example of the thalidomide affair highlights the dangers inherent in the production of the wrong polymorph,” she adds.

Diamond lights up crystal nucleation

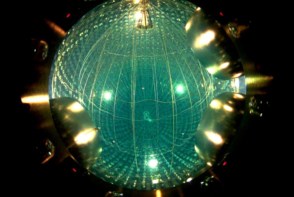

If that’s the back-story, what of the experimental detail? Front-and-centre in this regard are the big-science capabilities of Diamond Light Source, the UK’s national synchrotron research facility (located at the Harwell Science and Innovation Campus, Oxfordshire). Globally significant, Diamond is among an elite cadre of large-scale X-ray sources that is shedding light on the structure and behaviour of matter at the atomic and molecular level across all manner of fundamental and applied disciplines – from clean-energy technologies to pharma and healthcare; from food science to structural biology and cultural heritage.

Over the past decade, Povey and her team have been regular visitors to Diamond’s I22 beamline which, since entering operation in 2007, has hosted a dedicated programme for soft-matter and polymer research as well as activities in biological materials and environmental science. At I22, for example, the Leeds team is able to conduct X-ray diffraction (XRD) studies on a multipurpose instrument that combines small-angle and wide-angle X-ray scattering (SAXS/WAXS) modalities. The beamline also comprises a versatile sample platform to support in operando experiments – following structural evolution in solutions and melts, for example, over timescales from milliseconds to minutes.

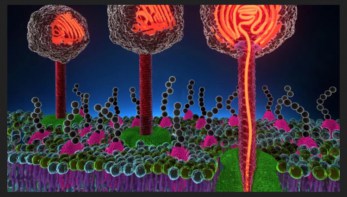

In terms of core specifications, the I22 insertion device delivers X-rays to the sample with energies between 7 and 22 keV (and a beam size of 240 × 60 microns for the main beamline). “The simultaneous recording of both SAXS and WAXS data in tandem means we can probe all length scales with high resolution – from a few angstroms up to the mesoscale at several hundred nanometres [and billions of molecules],” explains Povey. “Using a specially designed acousto-optic cell on the I22 beamline, we have accumulated experimental evidence for two-stage crystal nucleation as well as the impact of non-cavitational ultrasound on each step in the nucleation process.”

A case in point is a series of XRD studies tracking the crystallization of a wax (eicosane) from an organic solvent in the presence and absence of an insonifying ultrasound field. The goal: to investigate the effects of insonification both on the long-range order of eicosane molecules (via SAXS) and on the nanoscale molecular packing (using WAXS). In this way, Povey and colleagues have been able to identify mesoscale effects due to insonification that are absent in the quiescent fluid. The SAXS/WAXS investigations also enabled the Leeds team to characterize – and follow dynamically – the size of the regimes that precede the crystal nucleation step (in advance of initial crystal embryos transitioning into uncontrolled crystal growth).

“We’ll start with the wax emerging out of solution, for example, and follow that process at around 5-6 frames per second,” Povey explains. What they see in the first instance is the emergence of long-range order in the liquid under the influence of sonication. Then, in an increasingly saturated solution, this long-range order transitions into a phase separation in the so-called “dead zone”, which hosts the first stage of nucleation before the formation of crystal embryos. “At all stages,” she adds, “the low-power ultrasound can alter the molecular ordering and we see those effects unfold like a movie in real-time on I22.”

We think our insonification technique could rewrite the rules in injection moulding – reducing waste, reducing cost and increasing versatility in favour of sustainability

Megan Povey

Complementing the I22 SAXS/WAXS experiments, Povey and graduate student Fei Sheng have also used pulse-echo ultrasound techniques (pulse width of the order of 5 μs) to quantitatively monitor the behaviour of crystal embryos in supersaturated solutions (i.e. containing more than the maximum amount of solute that is capable of being dissolved at a given temperature). Using ultrasound to probe an aqueous copper sulphate sample in the acousto-optic cell, they were able to measure the coming into existence and subsequent disappearance of solid material associated with crystal embryos.

It’s this ability to monitor and control emergent crystal nuclei in the dead zone – where crystallization behaves like a casino in the absence of acoustic control – which has the potential to transform a wide range of industrial processes. One near-term commercial opportunity already under discussion with industry partners is the formation of plastic parts by injection moulding – traditionally an energetically expensive and sometimes hit-and-miss process. “We think our insonification technique could rewrite the rules in injection moulding – reducing waste, reducing cost and increasing versatility in favour of sustainability,” claims Povey.

Out of the lab, into the factory

Meanwhile, the applied R&D effort is addressing other aspects of technology translation – notably the integration of Povey’s theoretical framework for insonification and crystal nucleation with dissipative particle dynamics (DPD) computational modelling (a mesoscopic simulation technique that’s relevant across a variety of complex hydrodynamic phenomena). The motivation here is to develop a predictive method capable of modelling the impact of low-power ultrasound fields on a wide range of nucleating systems – and, by extension, control crystal formation reliably and repeatably.

Activity on the DPD front is led by Lewtas Science and Technologies, a UK consultancy specializing in advanced materials, working in collaboration with the Hartree National Centre for Digital Innovation, a UK outfit that supports technology transfer and commercialization in advanced computing and software.

You are what you eat

Significantly, Povey and Ken Lewtas, a polymer scientist who heads up the eponymous consultancy, have also filed an international patent to protect the intellectual property around the use of insonification in a range of industrial contexts, including (but not limited to) the tempering of chocolate (the process of slowly heating and then cooling chocolate so that the fat molecules crystallize into chocolate with the desirable properties of gloss, snap and cooling in the mouth); the crystallization of thermoplastic polymers (to control mechanical, optical or barrier properties); and even the waxing of diesel fuels and heating oils (which can impact fuel flows at low temperatures).

“Our hope,” concludes Povey, “is that industry partners will, sooner rather than later, be in a position to routinely apply our insonification technique and low-power ultrasound to promote or suppress crystallization across diverse production processes.”

The secrets of success in synchrotron science

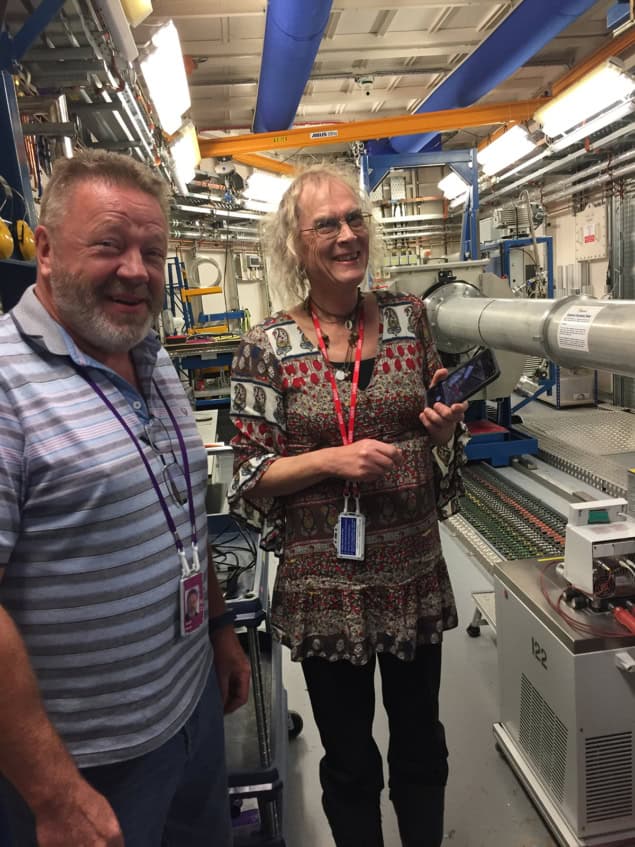

Nick Terrill is the principal beamline scientist for Diamond’s I22 multipurpose SAXS/WAXS facility. Here he tells Physics World how his team of five staff scientists is supporting the University of Leeds food physics programme in sonocrystallization.

How much planning goes into a multiyear research effort like this?

Our interaction with Megan and colleagues starts well in advance of their in situ beam-time at I22. As such, the requirements-gathering involves virtual and on-site meetings over a period of several months to ensure we’re all talking the same language and that the experimental set-up on the beamline is optimized to deliver the data they need, when they need it. There are no short-cuts, just exhaustive preparation: it takes a lot of planning and iteration to ensure the scientific users get good-quality results while they’re here at I22 for the three or four days of experiments.

Presumably there’s a lot of focus on system integration?

Correct. In this case, we spent a lot of time working with Megan and the team to figure out how to integrate their ultrasound instrumentation and acousto-optic sample cell into the beamline such that they didn’t compromise SAXS/WAXS data collection. I22’s dedicated Sample Environment Development Laboratory (SEDL) is crucial in this regard – basically an offline carbon-copy of the main beamline without the X-rays. Thanks to SEDL, external scientists can bring along their specialist kit – in this case, the ultrasound and acousto-optic subsystems – and work closely with the I22 team to ensure the hardware/software integration is as good as it can be prior to running live experiments.

What’s the secret of a successful collaboration between your team and the I22 end-users?

Our job is translate external users’ scientific objectives into realistic experiments that will run reliably on the beamline. You can only achieve that with open dialogue and two-way collaboration. With Megan’s team, we had to triangulate to make sure a range of modalities work seamlessly together – ultrasound diagnostics, ultrasound excitation and XRD data collection. The best collaborations are always a win-win, in that we also learn a lot of lessons along the way. That learning is key to our continuous improvement as a team and the ongoing scientific support we offer to all our I22 end-users.

Further reading

M J Povey et al. 2023 ‘Sounding’ out crystal nuclei – A mathematical-physical and experimental investigation J. Chem. Phys. 158 174501