Lake Shore Cryotronics’ M81-SSM offers DC, AC and lock-in source and measurement.

Today’s measurement systems can get very complicated very quickly. Scientists working at the cutting edge of research will often have to cobble together instruments from a number of different suppliers. This is problematic because mixed-vendor systems can be difficult to operate and this can seriously compromise the accuracy and repeatability of the measurements being made.

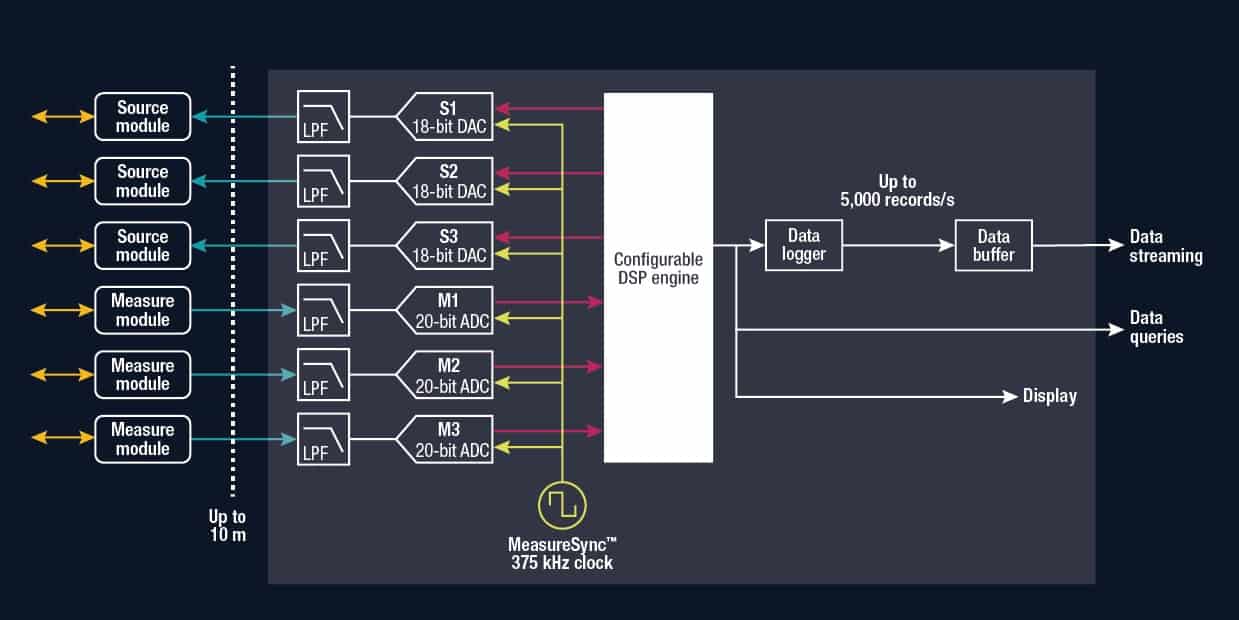

Lake Shore Cryotronics has addressed these uncertainties with its MeasureReady M81-SSM (Synchronous Source and Measure) system, which allows up to three source and three measurement modules to be simultaneously operated by a single central control instrument. The M81-SSM uses Lake Shore’s proprietary MeasureSync technology to ensure that all connected source and measure modules are synchronously updated and sampled well within +/-10 ns of each other at a 375 kHz sampling rate.

“We purposely put synchronous source and measure capabilities together,” explains Chuck Cimino, who is senior product manager at Lake Shore. “This also enables use of a common accuracy reference to the sample being characterized and ensures consistently minimal noise performance.”

The company is headquartered in Westerville, Ohio and has been developing measurement and control solutions for 56 years. “We’ve got multiple patented technologies in the M81-SSM that very much enable superior synchronization, mixed DC and AC sourcing and measuring, and smoother/faster voltage measurement range changing,” he adds.

At the heart of the M81-SSM is a controller instrument that currently supports four different types of source and measurement modules: a constant voltage source module; a balanced or differential constant current source module; a greater than 1 TΩ input impedance voltage measurement module; and a zero-offset voltage type current measurement module with programmable DC bias built in. Cimino says that more application-specific type modules are being developed to expand the system’s capabilities.

Extremely low-noise operation

All M81-SSM modules contain linear amplifier electronics that are powered by highly-isolated linear power supplies. Cimino says the result is extremely low-noise operation that exceeds many of the best conventionally-built single-box source and measure instruments, including a number of commonly used lock-in amplifiers.

The M81-SSM was designed from the start to cover the widest possible range of voltage versus current characterization applications with lowest possible noise and quickest configuration and setup for measuring samples in cryogenic and/or high field experiment environments. Lake Shore has extensive experience characterizing materials and devices in these and other extreme environments and has also fully leveraged proprietary signal conditioning and measurement technologies, as well as the company’s application scientists’ expertise, in the design of the M81-SSM.

This low-power and low-noise signal capability makes the M81-SSM very useful for measuring magnetic field effects using various Hall bar structures and magnetic field sensors. These devices are used in a number of applications, including spin transport experiments and the study of superconducting materials at cryogenic temperatures. As well as making measurements at very low temperatures while minimizing self-heating, the M81-SSM can also characterize materials in room and very high-temperature environments, avoiding thermal offsets via AC sourcing with lock-in detection.

Hall bar measurements, which are used to make very precise measurements of a sample’s electrical resistance, can be done very effectively using the M81-SSM’s differential current source and voltage measurement module combination. General four-wire resistance measurement applications also benefit from these low-noise, low-power fully differential connected modules.

The modular nature of the M81-SSM and the ability of the modules to switch easily between AC (up to 100 kHz), DC and lock-in detection modes gives users great flexibility in the types of measurements that can be done without swapping between or modifying dedicated DC and AC only instrumentation. This modularity and flexibility also means that the M81-SSM can be used to test multiple devices under identical conditions to deliver consistent results.

The VM-10 voltage measurement module can detect signals from the low nanovolt range up to 10 V. It operates from DC up to 100 kHz and can detect amplitude, phase and harmonics. The CM-10 current measurement module can detect currents in the femtoampere to 100 mA range. Current measurements can be made from DC to 100 kHz and include amplitude, phase and harmonic detection.

The BCS-10 balanced current source module is programmable from 100 fA to 100 mA from DC to 100 kHz sinusoidal output, while the VS-10 voltage source module provides programmable voltages from 1 µV DC/100 nV AC up to ± 10 V with DC to 100 kHz sinusoidal output.

The controller instrument offers a range of digital connectivity including USB, GPIB and Ethernet as well as interfacing with external reference sources or detectors. The controller and modules are compact benchtop instruments that can also be rack mounted.

Synchronization and integration

Thanks to its high degree of synchronization and integration of sourcing and measuring capabilities, the M81-SSM can reduce the number of separate instruments, in many cases to just the M81-SSM system, required to make precision measurements. This level of integration also minimizes the number and length of cables typically used to connect separate sources, measuring instruments and samples. This integration avoids the introduction of parasitic effects – such as leakage, noise, resistance and reactance – all of which can significantly degrade measurements.

The remote modules are connected to the main instrument via standard 2 m noise-immune power and signal cables, which can be optionally extended to 6 m total between instrument and any one module. This means that the modules can be placed very close to where the measurements are being made, such as in a cryogenic probe station. “The name of the game in low-level measurements is to minimize the length of the signal level cables,” says Cimino. “With the M81-SSM you can put the amplifier modules right next to the sample if desired.”

The modular nature of the system means that a wide range of configurations can be created by simply swapping connected modules. This makes the M81-SSM an extremely flexible system and its performance is more predictable than setups built of multiple separate instruments and instruments from different vendors. Furthermore, the entire system is supported by one supplier, making customer service and technical assistance simpler and more streamlined.

The M81-SSM uses a patented analogue system to transmit signals between the controller and its modules. Cimino explains that this keeps noisy digital circuits far away from the sensitive analogue circuits in the modules. This also minimizes ground errors and ensures the tight synchronization of all modules.

Dedicated ADCs and DACs

Signals from up to three connected measurement modules are digitized in the controller by dedicated analogue-to-digital (ADC) converters. Output signals from up to three source modules are defined by the controller by dedicated digital-to-analogue converters (DACs).

The ADCs and DACs are triggered by the rising edge of a shared MeasureSync clock signal. MeasureSync is Lake Shore’s patent-pending signal synchronization system that uses a common 375 kHz clock signal for updating and reading all modules – enabling continuous data sampling on every connected channel rather than the typical multiplexed multi-channel alternatives.

During the gaps between sampling clock edges, ADC data are read by the controller, and the DACs are set to provide the next output values. The result is the complete synchronization and continuous sampling of up to six connected amplifier channels – which means that several synchronized measurements can be made in parallel. Each channel can be set to perform AC, DC or lock-in measurements. Raw samples are acquired and processed at 375 kilosamples per second (kSa/s) and completed measurements are transmitted via LAN, USB or GPIB to a host PC at up to 5k records per second or an aggregate rate for 3 measure channels of 15k measurements per second.

This high degree of synchronization between source and measurement means that the M81-SSM can be used to make lock-in measurements that can extract very weak signals from noisy backgrounds. This is a significant benefit for users because lock-in measurements are usually done using a dedicated AC measurements-only lock-in amplifier instrument.

Lock-in at the touch of a button

“I’ve demonstrated for some interested customers the M81-SSM main capabilities and they ask ‘so where is the lock-in amplifier?’,” says Cimino. “Initially, they just see the compact modules and controller elements, and I have to explain that the lock-in is implemented digitally. ‘It’s a lock-in at the touch of a button’ is the enthusiastic response I got from multiple potential users.”

Cimino adds that novices and experts alike appreciate how simply and intuitively Lake Shore has configured the user interface. At the expert user end of the spectrum, Cimino says that “one M81-SSM user has adopted our Python driver as his group’s driver standard across all of his equipment. He just liked the way we abstracted the M81-SSM controls in our Python driver.”

“Or if you don’t want to program at all, our MeasureLINK software allows you to just drag and drop high-level source and measurement commands to stream data or to do long-duration testing,” says Cimino. “If you want to manipulate a magnetic field or a sample temperature while making electrical measurements, you can do that with no programming.”

Cimino describes the M81-SSM’s user interface as “discoverable” and that any smartphone user (i.e., “everyone”) would be comfortable using it. “Each module is represented in the interface and when you click on a module, you see a virtual front panel for that instrument,” he explains. The default settings on the interface correspond to the most common measurements, but users can also easily navigate the interface to control the M81-SSM in a way that matches their skill level and measurement requirements. And for the novice and expert user alike, Lake Shore provides support from its team of PhD-level application engineers.

“The M81-SSM is the result of five years of really hard work by Lake Shore’s engineering and application teams,” says Cimino, adding that positive responses from the user community suggests that it was well worth the effort.