Oil and water famously don’t mix – at least, not without adding a surfactant such as soap to coax them into a stable combination. Now, however, researchers in France and US have turned this conventional wisdom on its head by showing that they can, in fact, mix without a surfactant. The finding could have wide-reaching implications for industries that make heavy use of such mixtures, including food, cosmetics, health, paints and packaging to name just a few.

A mixture of two immiscible liquids such as water and oil is known as an emulsion. When an emulsion is shaken vigorously, one of its component liquids may disperse into small droplets within the other. But if the emulsion is left to stand, its components invariably separate out again.

The main driver of this separation is that as droplets of each liquid move closer to each other, they coalesce into ever-larger droplets. To prevent this, a third component may be added that is amphiphilic, meaning that it has an affinity for the interface between the mixture’s two components. Today’s industrial emulsions rely on the use of such materials, which are termed surfactants. However, many surfactants are toxic for both humans and the environment. Reducing their use (or doing away with them altogether) would therefore be highly beneficial.

A counter-intuitive phenomenon

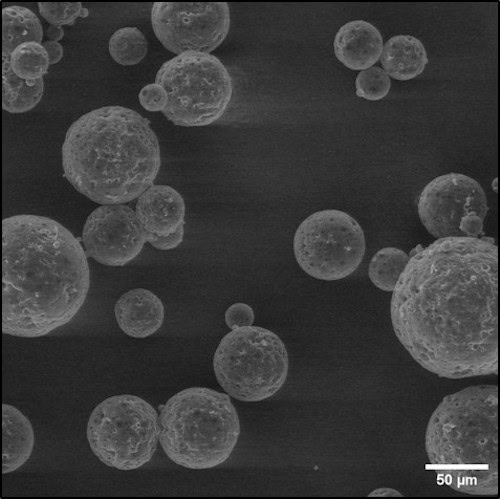

In the latest work, researchers from the Colloïdes et Matériaux Divisés Laboratory at the ESPCI in Paris, France; the French company Calyxia, which specializes in the design and manufacture of biodegradable microcapsules; and Harvard University in the US studied mixtures composed solely of water and various types of oil. Within these normally immiscible mixtures, they observed ultrathin but abnormally stable films of oil spontaneously appearing between the dispersed droplets of water.

“This phenomenon systematically induces adhesion between the droplets while preventing them from coalescing, so allowing us to disperse large proportions of water (80% by volume or more) in oil,” explains Jérôme Bibette, the chemical physicist and ESPCI laboratory director who led the research.

Stable over several weeks

The phenomenon, which is detailed in Science, works best for highly polar oils that contain both hydrophilic and hydrophobic components and have a high molecular weight. These criteria exclude aliphatic hydrocarbons such as methane and polyethylene, for example, but include oils containing alternating oxygen and carbon atoms – a category that encompasses all vegetable oils.

The researchers found that these oils can change their configuration as soon as they are confined between two drops of water by “choosing” to preferentially locate their hydrophilic parts towards the water and the hydrophobic parts away from it. “The ultrathin adhesive film induced by the affinity of the hydrophobic parts develops spontaneously as soon as the two interfaces approach,” Bibette says. “The film then acquires an enormous viscosity while reducing the free energy of the interface – something that manifests itself by the water and oil drops adhering together.”

Such spontaneous gelling between two immiscible liquids had never been observed before, he adds.

Colloidal mixture exists in up to six phases at once

Since most vegetable oils can be polymerized, combining them with water could allow researchers to make perfectly biodegradable polymeric materials. For Bibette, one of the most obvious applications that springs to mind is biodegradable capsules for industries such as cosmetics and fragrances.

The technique could also allow researchers to create new types of plastics comprising biodegradable polymers and up to 90% water by volume, he tells Physics World. “Both phases could be made (and controlled to be) homogenous throughout the entire mixture, which could allow us to produce a unique bi-continuous, coexisting hydrophilic and hydrophobic material,” he says. “This could have applications in areas as diverse as tissue engineering, biodegradable packing and materials for replacing plastics in general.”