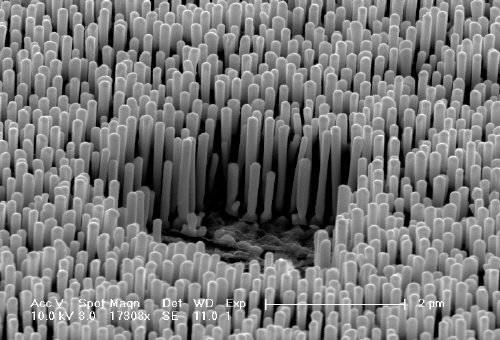

A new nanoimprinting technique that could come in useful for making high-density data storage and processing devices has been invented by mechanical engineers at Yale University in the US. The technique, which employs moulds made from amorphous metal rather than conventional silicon, can produce features as small as 13 nm — compared to the 45 nm features used in today’s computer chips. These can then be used to imprint onto polymers and other materials.

“We can now manipulate metallic glasses on extremely small scales, which were inaccessible in the past,” said team member Golden Kumar. “These glasses could be ideal materials for small-scale applications due to their superior mechanical and homogenous properties.”

Nanomoulding metallic glasses will have an important impact on nanoimprint lithography, which is regarded as the next-generation tool for nanoscale pattering, adds Kumar. Current nanoimprint technology relies on silicon-based moulds that are expensive to make and are not very durable. Nanoscale patterning such moulds also requires expensive and low-throughput electron-beam lithography.

Flow like plastics

The Yale researchers made their metallic glass templates by simple embossing techniques thanks to the fact that newly developed metallic glasses flow like plastics at moderately high temperatures. The metallic glass casts are stronger than silicon-based ones, can be massively replicated and are also reusable because features can be erased and the mould re-sculpted (Nature 457 868).

Kumar says that the moulds could be used as templates for nanoimprinting, rewritable high-density data storage, patterned surfaces for biomedical applications and photolithographic masks. “As well as these technological applications, the ability to precisely create metallic glass structures on the nanometre scale allows scientists to study the effects of size on the properties of amorphous materials — a subject that is hotly debated in the amorphous metal community,” added team leader Jan Schroers.

The researchers would now like to imprint even smaller features and study wetting phenomena between the different mould materials and metallic glasses. This will be the key to successful nanomoulding with metallic glasses, they explain.