An international team of researchers has developed an innovative system that can sterilize medical tools using solar heat. The device could help to maintain safe, sterile equipment at low cost in remote locations, and could prove particularly valuable in developing regions of the world.

The sterilization of invasive medical equipment is a critical step in mitigating infection risks in healthcare settings. However, although common sterilization procedures using saturated steam in a pressurized chamber – known as an autoclave – are effective and standardized worldwide, they can be a challenge to use in remote areas without reliable energy sources.

In an effort to address this issue, a team of researchers at Massachusetts Institute of Technology (MIT) and the Indian Institute of Technology Bombay have developed a novel way of generating high-temperature, high-pressure steam passively by using a portable solar energy collector. This steam is used to drive a typical small-clinic autoclave. The researchers describe their system in the journal Joule.

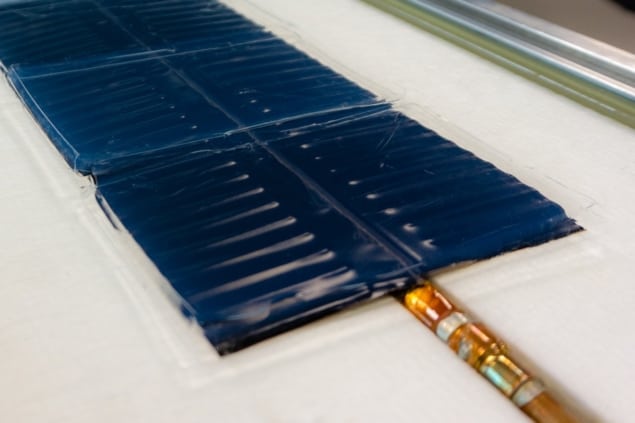

As MIT graduate student Lin Zhao – who wrote the paper alongside MIT professors Evelyn Wang and Gang Chen, and colleagues at MIT and IIT Bombay – explains, the researchers started to work on this problem after realising that a transparent silica aerogel material they had originally developed for large-scale concentrating solar-thermal power applications could also enable a “unique solution to medical sterilization with solar energy”.

After some research, the team found that the thermally insulating aerogel is particularly suitable because its operating temperature of around 125°C – beyond the 100°C limit of conventional passive solar water heaters, but without the complexity and cost of an active tracking system – is perfect for solar-powered sterilization applications.

“Because of [the system’s] relatively small-scale, it can also benefit greatly from a simple, modular design and it can have a high impact on people’s lives, especially in the developing regions,” says Zhao.

In a field test performed in Mumbai, the team simulated a clinical sterilization process by using a standard autoclave indicator tape – designed to change colour when sterilization conditions meet minimum exposure requirements – in a test chamber.

“The same tape is widely used in hospitals and clinics worldwide to verify the efficacy of their autoclaves,” Zhou explains. “As we showed in our paper, the tape changed colour after we completed the sterilization cycle in our device, validating the device’s sterilization efficacy.”

Next steps

Zhao points out that the device is likely to be of particular benefit for hospitals and clinics in remote locations, where electricity or fuel-powered autoclaves are too expensive or impossible to operate due to power shortages.

“Additionally, as we saw in India, centralized hospitals in big cities extend their healthcare service by setting up temporary clinics in remote villages,” he says. “Due to the lack of power sources, they have to carry sterilized equipment on every trip to the village, which limits the number of operations they can do. Our solar-powered device can help them sterilize the equipment on the spot, therefore increasing their capacity without adding more items to their packing list.”

Compared to existing solar-powered autoclaves, the new system has a number of advantages – including the fact that it is completely passive with no moving parts and its high energy efficiency, which enables it to provide more steam for a given footprint.

“Most of the components in our system are commercially available in the solar water heater industry. Once the aerogel becomes available, we expect our system can be mass-produced at low cost,” says Zhao.

Solar power brings medical imaging to Himalayan villages

The next critical step is to demonstrate feasible large-scale manufacturing of the transparent aerogel. As part of this process, AeroShield, a start-up company founded by co-author Elise Strobach, is developing a commercially viable manufacturing plan.

“After the aerogel material is available, we plan to partner with solar collector manufacturers such as AEi to produce our solar-autoclave prototypes and distribute them through local channels such as NGOs,” adds Zhou.