A reusable and biodegradable fibrous foam developed by researchers at Wuhan University in China can remove up to 99.8% of microplastics from polluted water. The foam, which is made from a self-assembled network of chitin and cellulose obtained from biomass wastes, has been successfully field-tested in four natural aquatic environments.

The amount of plastic waste in the environment has reached staggering levels and is now estimated at several billion metric tons. This plastic degrades extremely slowly and poses a hazard for ecosystems throughout its lifetime. Aquatic life is particularly vulnerable, as micron-sized plastic particles can combine with other pollutants in water and be ingested by a wide range of organisms. Removing these microplastic particles would help limit the damage, but standard filtration technologies are ineffective as the particles are so small.

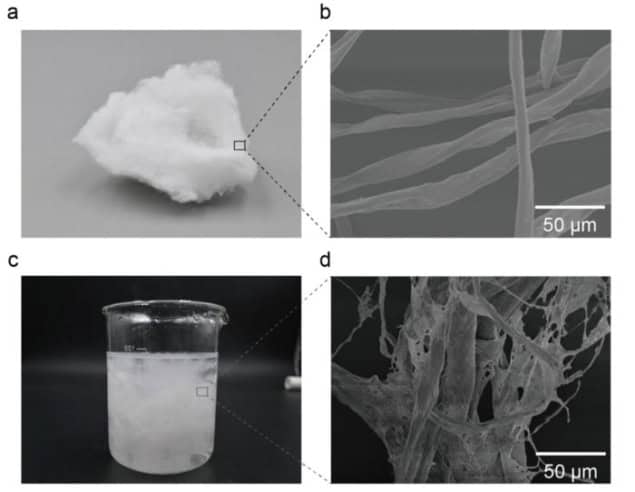

A highly porous interconnected structure

The new adsorbent developed by Wuhan’s Hongbing Deng and colleagues consists of intertwined beta-chitin nanofibre sheets (obtained from squid bone) with protonated amines and suspended cellulose fibres (obtained from cotton). This structure contains a number of functional groups, including -OH, -NH3+ and -NHCO- that allow the structure to self-assemble into a highly porous interconnected network.

This self-assembly is important, Deng explains, because it means the foam does not require “complex processing (no cross-linking and minimal use of chemical reagents) or adulteration with toxic or expensive substances,” he tells Physics World.

The functional groups make the surface of the foam rough and positively charged, providing numerous sites that can interact and adsorb plastic particles ranging in size from less than 100 nm to over 1000 microns. Deng explains that multiple mechanisms are at work during this process, including physical interception, electrostatic attraction and intermolecular interactions. The latter group includes interactions that involv hydrogen bonding, van der Waals forces and weak hydrogen bonding interactions (between OH and CH groups, for example).

The researchers tested their foam in lake water, coastal water, still water (a small pond) and water used for agricultural irrigation. They also combined these systematic adsorption experiments with molecular dynamics (MD) simulations and Hirshfeld partition (IGMH) calculations to better understand how the foam was working.

They found that the foam can adsorb a variety of nanoplastics and microplastics, including the polystyrene, polymethyl methacrylate, polypropylene and polyethylene terephthalate found in everyday objects such as electronic components, food packaging and textiles. Importantly, the foam can adsorb these plastics even in water bodies polluted with toxic metals such as lead and chemical dyes. It adsorbed nearly 100% of the particles in its first cycle and around 96-98% of the particles over the following five cycles.

“The great potential of biomass”

Because the raw materials needed to make the foam are readily available, and the fabrication process is straightforward, Deng thinks it could be produced on a large scale. “Other microplastic removal materials made from biomass feedstocks have been reported in recent years, but some of these needed to be functionalized with other chemicals,” he says. “Such treatments can increase costs or hinder their large-scale production.”

Microplastics with elongated shapes travel further in the environment

Deng and his team have applied for a patent on the material and are now looking for industrial partners to help them produce it. In the meantime, he hopes the work will help draw attention to the microplastic problem and convince more scientists to work on it. “We believe that the great potential of biomass will be recognized and that the use of biomass resources will become more diverse and thorough,” he says.

The present work is described in Science Advances.