Holograms that respond to physical, chemical and biological stimuli are providing new diagnostic tests with applications ranging from aviation to medicine, describe Chris Lowe and Cynthia Larbey

At least 6% of world trade, amounting to some $200bn per year, involves counterfeit goods. But this figure would be even higher were it not for the humble hologram. Invented 50 years ago, holograms provide authentication tags to deter copying, and can be found everywhere from credit cards, passports and banknotes to consumer goods, cosmetics and pharmaceuticals. Holography also underpins supermarket scanners and CD players; it can even be used to store optical data in 3D. Now, however, holograms are making their mark as powerful yet cheap diagnostic tools, which could in particular have many applications in biomedicine.

Until recently though, medical holograms were the stuff of science fiction. In the 1995 TV series Star Trek: Voyager, for example, the 24th-century crew tackles a band of Maquis rebels 70,000 light-years away, during which the ship’s doctor is killed and the crew has to rely on the “emergency medical hologram” for support. But science fiction is now turning into science fact, with several “smart” holograms for diagnostic and other applications about to hit the market.

Diagnostic tests are commonplace in the modern world — being used to assess everything from illnesses and food safety to security and bioterrorism. Currently, these tasks are carried out by measuring several chemical or biological parameters in readily accessible samples and then sending them to a central laboratory for analysis. Although such labs are often fully automated and do not even require the expertise of a scientist, it can still take several days before the results are returned — a delay that can hamper diagnosis.

There has been something of a revolution in medical diagnostics in recent years, with tests increasingly being brought to the patient. For example, tests conducted patient-side have reduced the time to analyse “cardiac markers” from days in a central laboratory to minutes, thereby hastening crucial medical decisions relating to heart attacks. Similar trends are apparent in water-quality monitoring, food and beverage assurance, and in environmental, military and anti-terrorism testing. Such “point-of-sampling” tests can also reduce the cost per test by more than a third, together with additional savings in manpower. However, since testing is often performed on the ground by lay staff and requires immediate interpretation, it is essential that the underlying technology is robust and accurate.

Sensors based on smart holograms, the optical properties of which change in response to external stimuli, are ideally suited for diagnostic testing. In addition to providing simple and reliable sensors with built-in read-out capabilities, such holograms are commercially viable because they can be made using established techniques from the microelectronics, printing and photographic industries. Indeed, the first such product — a sensor that can detect minute quantities of water in aviation fuel — is about to be launched by Smart Holograms, a firm spun-out from the Institute of Biotechnology at Cambridge University in the UK.

Unintuitive and baffling

The underlying theory for holography was developed in 1947 by the Hungarian-born physicist Dennis Gabor, for which he was awarded the 1971 Nobel Prize for Physics. Gabor’s discovery was serendipitous, made while trying to improve the resolution of electron microscopes, and at the time did not have any other known applications. Indeed, in September 1948 the New York Times described the hologram as “a futuristic tapestry that mysteriously recreates images out of thin air”, and until the late 1950s the technique was deemed “unintuitive and baffling”, of “dubious practicality” and even pronounced a “white elephant”! That view has since changed.

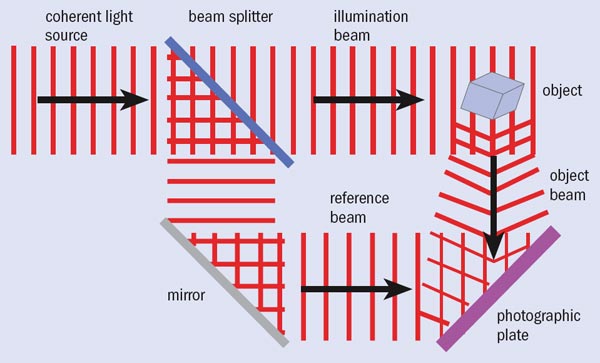

A hologram is a recording of an optical interference pattern between light waves. To generate a hologram, two coherent light beams — called the object and reference beams — are made to overlap in a photosensitive material such as a photopolymer or silver-halide emulsion. The object beam propagates from the object and thus carries information about it, while the reference beam is used to record the hologram (see “The basics of holography”). The optical interference pattern is physically stored as a change in absorption, refractive index or thickness of the recording material — turning it into a diffraction grating that contains information about the amplitude and phase of the two original light beams. By illuminating the grating with the reference beam, a weak copy of the original object beam can be reconstructed.

Despite understanding how a hologram would work, researchers were unable to develop Gabor’s idea until the invention of the laser some 10 years later. Having such a coherent light source is vital for holography, since the information stored in a hologram depends sensitively on the phase and wavelength of light (unlike the information stored in a photograph, which depends only on the intensity of light).

The first holograms that could record 3D objects were fabricated in 1962 by the US researchers Emmett Leith and Juris Upatnieks at the University of Michigan. These were called transmission holograms, since to view them one had to pass a laser through the hologram and observe the reconstructed image from the opposite side to that of the source. A later refinement, the “rainbow transmission hologram”, allowed holograms to be viewed in colour using plain white light. These holograms — which usually consist of a pattern on the surface of a plastic film coated on a reflective aluminium foil — are those used as security features on credit cards and other products. (The foil allows the light to come from behind the hologram to reconstruct the image.)

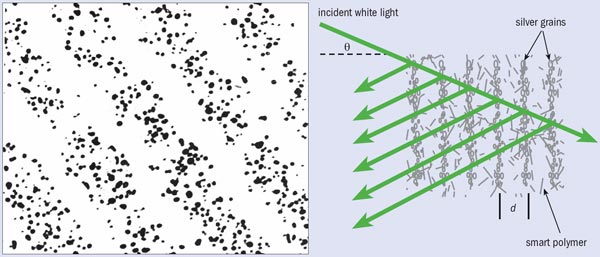

In the same year, the Soviet physicist Yuri Denisyuk at the Ioffe Institute in St Petersburg developed another common type of hologram: the reflection or Denisyuk hologram, which can reproduce multiple colours using white-light illumination on the same side of the hologram as the viewer. Denisyuk holograms use photographic emulsions made up of a polymer, a light-sensitive silver salt (silver bromide) and a photosensitizing dye coated onto glass or plastic substrates, and are constructed by passing a laser through the emulsion and returning it via reflection off a planar mirror that serves as the object. The standing-wave pattern created when the incident and reflected beams meet is preserved in 3D via layers of ultra-fine grains of metallic silver, which means the hologram relies on diffractive reflection from the silver grains (see “Smart holography”). To ensure that reflections from different locations interfere constructively with one other, the silver fringes must be spaced periodically. (Similar periodic structures are the cause of the vibrant colours produced when light reflects from a CD-ROM or certain “iridescent” butterfly wings.)

In 1999 the present authors found that Denisyuk holograms that are recorded with a single 10 ns pulse from a neodymium-doped yttrium aluminium garnet (Nd:YAG) laser offer similar brightnesses under the same exposure and processing conditions to those from commercially available holographic recording materials such as the biological polymer gelatin. This method of fabrication allowed holograms to be recorded in almost any polymer matrix, thus offering the prospect of holograms with optical properties that change in response to desired physical, chemical or biological stimuli. This laid the basis for a spin-out company called Smart Holograms, which was founded in 2004 (see section “From bench to market: the origins of Smart Holograms”).

Smartening up

In a smart hologram, a suitable complementary receptor is attached to the polymer matrix of the photographic emulsion such that the polymer undergoes a physical or chemical change when a substance of interest (called the analyte) binds to it. Thus, in principle, any physical, chemical or biological stimulus that interacts with the smart polymer will generate observable changes in the wavelength (i.e. colour), intensity (brightness) or encoded image of the reflection hologram.

The active component in such a “smart” hologram is normally a 3D polymer network called a hydrogel, which is a material that is very good at absorbing water and can swell anywhere up to 1000% of its original volume. By incorporating a hologram throughout the volume of a hydrogel, holographic gratings can be fabricated that respond to, for example, humidity, water, solvents, dissolved gases, ions, metabolites, drugs, antibiotics, sugars or enzymes. In most cases, the binding of the target analyte to the receptor in the hydrogel generates either a change in charge status, a covalent or non-covalent “crosslink” between neighbouring polymer chains, or a change in secondary interactions involving hydrogen bonding or hydrophobicity. What this means is that relatively small perturbations in environmental conditions can cause macroscopic changes to the volume of the hydrogel by it absorbing different amounts of water.

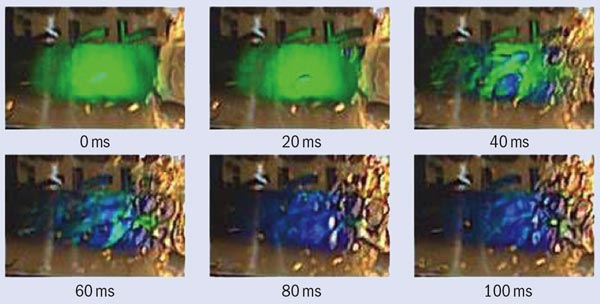

The structure of the interference fringes therefore gives the hologram a built-in indicator of the extent to which the hydrogel has expanded, whereby changes in the wavelength or intensity of the diffracted light, for example, can easily be quantified by eye. (Other common types of hologram, such as those found on credit cards, do not behave like this because their fringe structure is perpendicular to the plane of the substrate surface, which makes them insensitive to changes in the thickness of the supporting polymer film). Furthermore, since the fringe structure of smart holograms is not permanently altered, the hydrogel can undergo many cycles of swelling and contraction before returning to the same peak wavelength and reflectivity. Combined with their rapid response times, smart holograms offer great potential for monitoring changes in analyte concentrations in real time.

One of the simplest applications of holographic sensors is to measure directly the water activity in immiscible liquids. Immersing gelatin-based holograms in “wet” solvents causes water from the bulk solution to move into the holographic phase. The resultant swelling and consequent increase (i.e. redshift) in the diffraction wavelength is directly proportional to the water content of the sample. Holographic sensors thus generate a visual colour change, which provides a semiquantitative read-out without the need for additional instrumentation (see “Holograms for health”). As such, they can serve as power-free sensors of water activity in the petrochemical, food, textile, electronics and pharmaceutical industries, where water contamination can cause physical or financial damage.

Applied holography

Smart Holograms’ first product — a moisture-sensitive sensor called H2No — has been developed in conjunction with the global fuel supplier Air BP. Approximately 80 billion litres of aviation fuel were used in the US alone in 2006 and 42 million tests were performed for water contamination, often in extreme weather conditions. Water contamination can cause the fuel to freeze at high altitude, which can block filters with potentially disastrous consequences. It is usually identified by performing a somewhat subjective “clear-and-bright” test, in which a hazy visual appearance indicates water contamination beyond the acceptable limit of 30 parts per million (ppm). On the other hand, Smart Holograms’ device — a hand-held syringe that contains a holographic sensor some 1 cm in diameter — instantly generates an easily discernible red cross if the water content of the fuel is above this limit (see “Clear result”).

The company is also working with architectural glazing firms to develop a moisture sensor that can detect whether water has crept in between panes due to defective or damaged seals. Some 370 million double-glazing units are produced worldwide each year, and such defects can incur significant financial losses as well as reduce the energy efficiency of buildings. Furthermore, we anticipate that smart polymers can be painted, coated or sprayed as micron-thin layers onto, or incorporated into, a range of different surfaces or materials used in the construction industry. This would give architectural features certain interesting optical characteristics, for example being able to change colour or brightness, or display alphanumeric messages or images in response to specific agents. More than mere aesthetic value, this could help make buildings safer by allowing toxic gases or volatile organic compounds to be monitored, or be more comfortable by sensing changes in temperature, humidity and exposure to ultraviolet light.

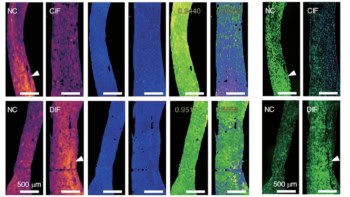

The ability to detect the presence of ions, metabolites and enzyme activity also makes holographic sensors ideal for medical diagnostics — in particular for monitoring disease-specific markers in the blood. In order to create pH-sensitive holograms, for instance, the gratings are recorded within hydrogels that contain acidic or basic monomers: ionization of the functional groups of the monomers causes the grating to swell or contract as a result of electrostatic and osmotic forces that draw or expel counter-ions and water into or out of the hydrogel phase. This movement changes the fringe separation of the hologram and causes longer or shorter wavelengths to be selected for reflection. As a result, the diffraction wavelength of the sensor hologram depends on the pH of the bulk medium.

Researchers at Cambridge have recently developed sensor holograms for potassium and sodium ions, with the aim of diagnosing kidney or adrenal disorders, diarrhoea and high blood pressure and also to monitor patients on kidney dialysis, diuretic or drip therapies. To this end, the hydrogel polymer was modified with specific receptors called crown ethers, which form strong reversible complexes with these metal ions in solution. In the case of one particular receptor, 18-crown-6, the wavelength of the holograms was found to be directly proportional to the concentration of potassium ions. In addition, the sensor was virtually unaffected by normal physiological variations in background sodium levels, thus highlighting its potential for use as a sensor for measuring potassium in the blood. Further work has shown that holograms can be used to detect other physiological ions, such as calcium (Ca2+) and magnesium (Mg2+).

Currently, Smart Holograms is developing a blood-glucose monitor to help diabetic patients monitor their glucose levels. Diabetes currently afflicts some 6% of the world’s population and cases are expected to double by 2025. Most patients currently measure their blood-glucose levels using a disposable enzymatic electrochemical device, but holograms made from hydrogel films containing a polymer matrix modified with a specific glucose receptor (phenylboronic acid) offer a cheaper alternative that can also monitor glucose levels continuously.

Early studies by the Cambridge researchers have shown that the wavelength of sensor holograms increases as a function of glucose concentration across the normal physiological glucose range. Smart Holograms is now assessing the performance of these sensor holograms in complex biological media, with the goal of producing a device that will allow patients to test their blood-glucose levels for themselves. Such a sensor might be incorporated into a suitable indwelling catheter with a fibre-optic sensor to detect the output, for example, or into a contact lens that could continuously monitor glucose levels in the tear fluid of the eye. Such approaches do not require regular calibration and the diagnostic is continuous, accurate and responds in real time (see “Holograms for health”).

Researchers have used similar holographic sensors to monitor the depletion of glucose during the growth of the spore-forming organism Bacillus subtilis — a close relative of Bacillus anthracis, which causes anthrax and is thus a potential biological weapon. In this case, holograms offer considerable advantages over conventional enzyme-based sensors that use straightforward biochemical reactions because they do not consume glucose and therefore do not reduce substrate levels in small-volume samples, which could give an inaccurate result. We are now assessing the potential of such a sensor as a rapid anthrax-identification system for use by the emergency services following a terrorist incident.

Smart and secure

In this article it has only been possible to summarize some of the most developed applications of holographic sensors, but the potential of smart holography is huge. For example, smart holograms could allow researchers who are looking for new drugs to rapidly screen large numbers of potential molecules. The technique could also help in process development. Sensor holograms have already been used to monitor the metabolic products of small (~300 nl) microbial fermentations, for example, by monitoring the spoilage of milk by Lactobacillus casei via the change in pH generated during the fermentation process. Indeed, such sensors could be used to alert consumers when milk has actually gone off without relying on a date stamp and so could thus become a quality standard in supermarkets.

Moreover, the fact that the visual images produced by smart holograms can be made to appear or disappear under appropriate chemical or biological stimuli — and so be used to display visual interpretations of the analyte concentrations — make them ideal for use in Breathalysers, monitoring heart conditions and for various security and “smart” packaging systems. Smart Holograms already offers a range of brand-protection products based on multiplexed high-definition images that are extremely difficult to copy. The firm is also developing new “particulate holograms” for use in cosmetics, paints, printing inks and coatings for leisure, toys and to monitor toxic environmental gases, where sensors covering large areas are required.

Sensor holograms are virtually impossible to reverse engineer or replicate, are “format-flexible” to meet individual requirements, do not require a power source, are scaleable to any dimension, can be read in parallel, and are fabricated by a manufacturing process that is readily integrated into existing supply chains. Thus, in the 21st century, unlike the 24th century, we do not have to embellish the storyline with colourful Star Trek characters to introduce yet new applications for holographic technology. That technology is here already.

From bench to market: the origins of Smart Holograms

The technology on which Smart Holograms is developing its products originated in the late 1990s in the group of one of the present authors (CL) at the Institute of Biotechnology at Cambridge University in the UK. Along with physicist Roger Millington, CL conceived of the idea while investigating new inexpensive approaches to optical biosensors, and the concept was further elaborated by then PhD student Jan Groves, holographer Jeff Blyth and biochemist Andrew Mayes. This early work established most of the key underlying concepts of responsive holograms (which were covered by four patents), while a proof-of-concept grant for £25,000 from the university funded an initial study to assess the feasibility of establishing a new company.

Smart Holograms was established in 2004 on the basis of the granted and filed patent applications together with funds from the University of Cambridge Challenge Fund (£250,000), the Small Business Research Initiative operated by the Biological Biotechnology and Biological Sciences Research Council (£216,000), a contract from a leading pharmaceutical company (£400,000) and venture-capital funding (£5m). Today, the firm employs over 40 staff in Cambridge, has protected its intellectual property with some 40 filed/granted patents and seven filed trademarks, and signed co-development deals with blue-chip industry leaders. Its core technology is “smart” holograms that change in response to external stimuli, with applications in the brand-protection, verification and healthcare industries.

Smart Holograms’ first generation product (H2No) is designed to detect moisture in aviation fuel. Early work at Cambridge’s Institute of Biotechnology showed that kerosene contaminated with 100 parts per million (ppm) of water could change the colour of a gelatin hologram from green to red by partitioning the water into the holographic phase and thereby expanding the Bragg diffraction planes and redshifting the replay wavelength.

In 2005 Smart Holograms established a development programme with the support of the fuel company Air BP to create a point-of-sampling test for water contamination in aviation fuel. H2No is a disposable holographic sensor that generates a red “×” on a green background when the free water concentration is above 30 ppm. The system has patent protection, is trademarked and has undergone extensive laboratory and field trialling at several Air BP locations. A key factor in introducing the test to the market was to establish a manufacturing capability at Smart Hologram’s Cambridge facility that could produce the 42 million or so test units required per annum.

At a Glance: Smart holograms

- Holograms, which are recordings of optical interference patterns, are widely used as authentication tags and in data storage

- Most holograms are fixed in a photosensitive material, but recently researchers have created “smart” holograms by fabricating them in materials such as hydrogels that are sensitive to environmental conditions

- As hydrogels can swell or contract in response to specific physical, chemical or biological agents, smart holograms can be used as diagnostic sensors, and often have a clear visual output

- Smart Holograms — a firm that was spun-out from Cambridge University in 2004 — has already launched its first product: a sensor that can detect water in airline fuel

- One of the biggest potential markets for sensor holograms is the field of medical diagnostics, such as providing diabetes sufferers with a simple and reliable blood-glucose monitor

More about: Smart Holograms

J Blyth et al. 1999 A diffusion method for making silver bromide based holographic recording material Imaging Sci. J. 47 87–91

C R Lowe 1999 Chemoselective biosensors Curr. Opin. Chem. Biol. 3 106–111

C R Lowe 2007 Holographic sensors Handbook of Biosensors and Biochips (ed) R S Marks et al. (Wiley, Chichester) pp587–596

G Saxby 1994 Practical Holography (Prentice Hall, Englewood Cliffs)

Smart Holograms Ltd: www.smartholograms.com