The unusual optical features of liquid crystals make them indispensable in many technologies, including displays and optoelectronics. Now Baek-woon Lee and Noel A Clark of the University of Colorado, US, have developed a 'patterned' base layer for liquid crystals that overcomes a long-standing difficulty in controlling the molecules in the liquid crystal. The new technique is an important step towards the simple fabrication of highly intricate liquid-crystal devices using lithography (Baek-woon Lee and Noel A Clark 2001 Science 291 2576).

The rod-shaped molecules of a ‘nematic’ liquid crystal lie at about the same angle to the substrate, but they can orient themselves in any direction around the normal. This gives rise to a property known as birefringence, in which the liquid crystal has many different refractive indices, depending on which direction light enters the crystal. The degree of birefringence can be controlled by aligning the molecules using an electric field and by adjusting the molecular make-up of the surface on which the liquid crystal is created. When the molecules are lined up, the birefringent crystal splits incoming rays of light into two polarized beams – one polarized along the direction of orientation of the molecules, and the second exactly perpendicular to the first.

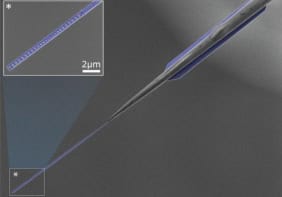

But the development of existing substrates has been a painstaking process of trial and error, and involved roughening the surfaces. Now Lee and Clark have discovered a simpler way to align the molecules. They deposited a thin layer of a silicon-based material onto a glass wafer, and then shone ultraviolet through a stencil to remove narrow strips of the material in a process akin to lithography. Tiny cells on this surface were then filled with the liquid crystal. Lee and Clark found that molecules in neighbouring smooth patches of liquid crystal line up with the molecules in the specially created boundary regions.

The new technique could open the door for the easy preparation of surfaces using lithography. “Virtually any complex pattern of alignment can be fabricated with ease at micrometre resolution”, say Lee and Clark. The researchers also believe the method could be used to manufacture two-dimensional photonic bandgap structures.