Scientists in Sweden have developed a novel technique for making micromachines and demonstrated its potential by making a micro pinball table. Martin Bring and colleagues at the Chalmers University of Technology and the Institute of Microelectronics in Gothenburg believe that their process overcomes many of the problems associated with the ‘dry etching’ step that is conventionally used to fabricate silicon-based microelectromechanical devices, and say that it could provide an easy and robust alternative to existing methods (M Bring et al. 2003 J. Micromech. Microeng. 13 S51). Silicon micromachines are used in applications as diverse as transducers in sensors, micromirros in digital projectors, and optical switches.

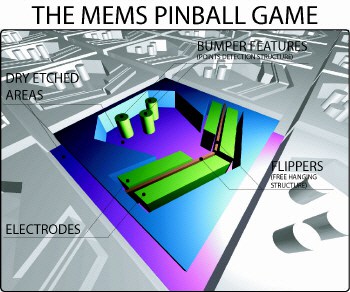

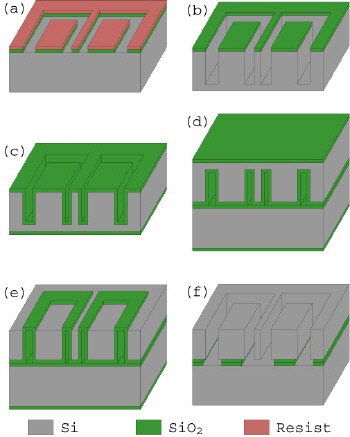

Bring and colleagues built a micro pinball table in which silicon cantilevers acted as the ‘flippers’, magnetic beads 150 microns in diameter were the balls, and the table measured 25 millimetres square. They started with two 700-micron thick wafers of single crystal silicon and used a combination of oxidation, patterning and dry etching – with an additional oxygen plasma bonding step – to make the device (figure 1).

The patterning involves only one step – compared with several steps for traditional methods. Moreover, the plasma bonding takes place at room temperature, which means that a wider choice of materials can be used to make the devices. The high temperatures involved in current fabrication techniques limit the materials that can be processed.

The researchers put in the balls ‘by hand’ and tilted the table at an angle of 20 degrees to the horizontal (figure 2). They found that the speed of a ball could reach up to 0.75 kilometres per hour – or 210 000 microns per second. This is equivalent to a football having an almost supersonic speed of 1125 km per hour (see ‘related links’ for a short film of the game).

“The pinball games are used for demonstrating this simple and easy process,” Brings told PhysicsWeb. “It also demonstrates some of the effects that occur on the micrometer level, such as small apparent inertia.” The team says that the process could be used to build devices such as spatial light modulators, micromotors, optical switches and viscometers.