Physicists at Philips Research in the Netherlands have developed a new way to make “electronic paper” that could display moving images. Robert Hayes and Johan Feenstra say that their electrowetting technique could be used to make a reflective display that is four times brighter than reflective liquid-crystal displays (LCDs). Their approach relies on using low voltages to move a coloured film of oil (R A Hayes and B J Feenstra 2003 Nature 425 383).

Electronic paper combines the advantageous viewing characteristics of conventional paper with the ability to electronically manipulate the information displayed on the paper. Researchers have made electronic paper before but it has always been expensive and slow to switch from one colour to another.

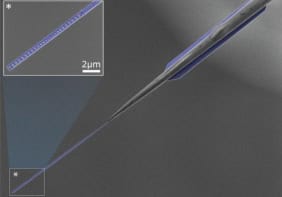

Hayes and Feenstra started by coating a white polymer foil substrate with a patterned electrode layer and a hydrophobic fluoropolymer insulator. The electrode layer was made of indium tin oxide and was just 15 nanometres thick. Then they made small ‘walls’ to define the pixels and added a layer of coloured oil – about 10 microns thick – followed by a layer of water (figure 1a).

In the absence of any applied voltage the coloured oil forms a flat film between the water and fluoropolymer, which results in a coloured pixel. When the researchers apply a voltage of about -20 volts between the electrode and water, the interfacial tension between the water and the fluoropolymer changes. This means that the system is no longer stable and the water causes the oil to move to one side, thus exposing the white surface beneath (figure 1b).

Switching between white and coloured reflections takes less than 10 milliseconds, which is fast enough for video displays. Moreover, the researchers found that if they added a second layer of oil, they could further improve the reflectivity – to four times that of an LCD.

“Achieving high reflectivity and video-speed capability are needed for reflective displays to be successful,” Hayes told PhysicsWeb. “Our new display technology is an important step in both these directions.” The pair say that as well electronic paper, their technique will be useful to make displays for mobile and outdoor applications. “We now hope to industrialize this new technology and make larger, active-matrix displays,” said Hayes.