Material scientists from Denmark have developed an X-ray microscope that can follow the changes that take place in a metal during the process of recrystallization in three spatial dimensions and one time dimension. Preliminary results obtained with the device show that the growth of metallic grains during the process is less smooth and regular than predicted by theory (S Schmidt et al. 2004 Science 305 229). Recrystallization is an important step in the production of metals.

“We are now able to see in-situ the full three dimensional shape of a single grain as it evolves during recrystallization in the interior of a sample,” says Soeren Schimdt of the Riso National Laboratory in Denmark. “One could say that we have a full four dimensional (4D) description of the grain. This is the first time ever this has been obtained.”

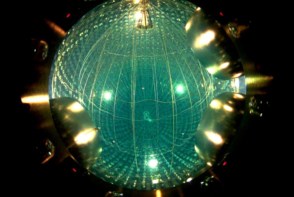

The four-dimensional microscope is a modified version of the Three Dimensional X-Ray Diffraction (3DXRD) microscope at the European Synchrotron Radiation Facility (ESRF) in Grenoble. Schimdt and colleagues from Riso and the ESRF used a beam of 50 keV X-rays from the ESRF to study a single crystal of aluminium that had been deformed enough to ensure that recrystallization would occur.

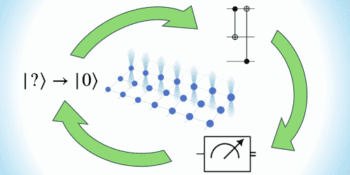

The Danish scientists started by positioning their sample in the 3DXRD microscope so that the X-ray beam intersected a single recrystallizing grain. Next, they made a series of vertical cuts across the grain and took images of the successive cross-sections. By then stacking these images together, they were able to obtain a full three-dimensional image of the grain. The procedure was repeated several times to produce a movie of the process (see Related links).

The team now plans to investigate recrystallization in other situations. “Hopefully we can combine these results and come up with a more fundamental description of the recrystallization process,” says Schmidt.