Engineers in the US have built the first life-sized fully micromachined artificial cochlea. The device made by Robert White and Karl Grosh at the University of Michigan works in the same way as the cochlea in a real ear. It could be used to make cochlear implants in hearing aids as well as sensors for commercial and military applications (Proc. Nat. Acad. Sci. 102 1296).

The cochlea is a small spiral-shaped organ in the inner part of the ear where sound vibrations are converted into nerve impulses, which are then sent to the brain as electrical signals. The human cochlea occupies a volume of about 1 cubic centimetre and operates at frequencies between 20 hertz and 20 kilohertz. It can detect sounds over a range of 120 decibels.

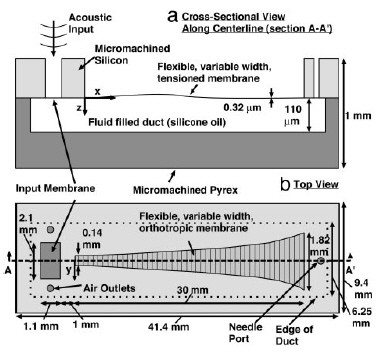

White and Grosh employed a micromachining technique known as “deep reactive ion etching”, which is an extension of the techniques that are used to make integrated circuits, to fabricate the device (figure 1). “Micromachining allows us to define very small features and produce devices economically in large batches,” Grosh told PhysicsWeb.

The cochlea consists of ducts filled with water-like fluids. The cochlea can be thought of as being divided into two channels by a flexible basilar membrane. When a sound wave enters the cochlea, it creates a wave in the fluid that travels along the basilar membrane. This movement is then detected by sensory hair cells on the membrane (figure 2). Our ears can distinguish between different tones or frequencies because the waves created by high frequencies have a maximum near the base of the cochlea, while lower frequencies travel further towards the apex. The mechanical cochlea works in the same way.

White and Grosh now plan to add sensing elements and electronics to the device so that they can increase both its sensitivity and the range of sounds that it can hear.