Since high-temperature superconductors were discovered two decades ago, technologists have dreamed of low-loss electrical transmission lines, levitating trains and super-efficient motors. But applications such as these have been slow to materialize. Now, Amit Goyal and colleagues at the Oak Ridge National Laboratory in the US have introduced nanoscale defects into a "cuprate" superconductor to create short lengths of wire that can carry large currents and work in strong magnetic fields. If the wires can be scaled up to kilometre lengths then they could revolutionize applications of high-temperature superconductivity (Science 311 1911).

Superconductors are materials that lose their electrical resistance when cooled below a certain temperature. Most superconductors have transition temperatures of just a few Kelvin, but in 1986 a new class of high-temperature superconductors with transition temperatures of up to 100K was discovered. These high-temperature “cuprate” superconductors consist of layers of copper oxide, separated by metal atoms such as yttrium and barium, and the supercurrent is thought to flow through the copper oxide layers.

Turning these compounds into commercially useful wires, however, has proved difficult. For example, it is hard to grow wires thick enough to carry sufficient current, and the superconducting behaviour can be destroyed when the wires are exposed to the very strong magnetic fields generated in motors and power-transmission cables. Goyal’s team have made progress on both these fronts using a technique called pulsed laser ablation to deposit a 3-micron-thick film of yttrium barium copper oxide (YBCO) onto a flexible metal substrate.

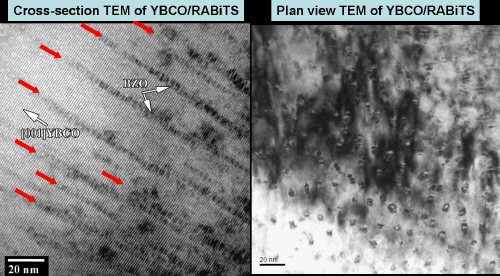

According to Goyal, there was no single trick to getting the technique right to make thicker wires, but the researchers adopted a new approach to making the wires immune to magnetic fields by adding a barium zirconate (BZO) nanopowder to the YBCO starting material. During wire growth, the BZO arranges itself into columns of self-aligned nanodots within the superconductor. These columns of nanodots act as extended defects that effectively pin down the magnetic flux entering the wire, allowing large currents to flow through the superconductor even when a high magnetic field is applied.

“Our work demonstrates that it is indeed possible to fabricate superconducting wires with the performance levels needed for a whole range of large-scale applications,” says Goyal. “If successfully made in long lengths, wires with such nanoscale defect structures could revolutionize the electric power industry.” The wires might also find use in the military, medicine, high-speed transportation and high-energy physics. The team now hopes to achieve similar nanoscale defects in thicker films and so obtain even better performance.