As any experienced angler will know, some knots are better than others -- but exactly why a "blood knot" should be stronger than, say, a "reef knot" is far from clear. Now, physicists in Japan have tried to unravel this mystery by carrying out the first experiments into how fishing lines with knots in them actually break. Surprisingly, it turns out that some knots that are strong when made using traditional nylon fishing line are in fact the weakest when made in a more modern material called PVDF (New Journal of Physics 9 65).

Determining exactly where a knot breaks in a material is not easy. First, the shape of the knot changes as it is tightened. Second, it is difficult to watch how the broken strands recoil, which takes place very quickly. Third, most knots unravel after breaking, making it hard to reconstruct a broken knot.

Hiroki Uehara and colleagues at Gumna University have now found a simple solution to these knotty problems. They first stretched a knot to nearly its breaking point and then daubed ink onto the exposed portions of the knot – leaving the internal portions of the knot unstained. After the ink had dried, they continued to pull until the knot broke. By comparing the ink patterns on the strand before and after breaking they were able to determine exactly where the knot failed.

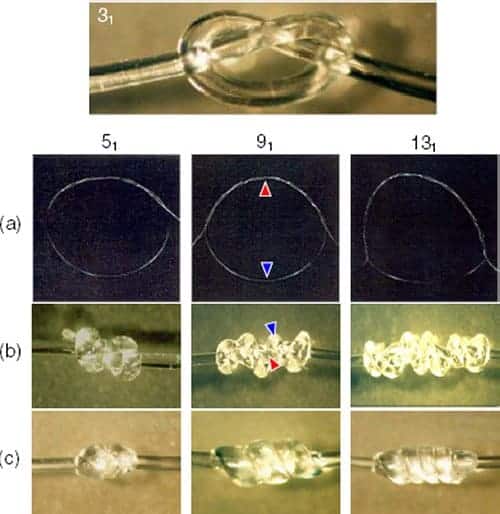

The researchers focused on simple “torus” knots, which can be characterized in terms of how many times the strand crosses over itself in the knot (see figure). When the knots were made in the PVDF (poly(vinylidene fluoride)) material, Uehara and colleagues were surprised to find that knots with the lowest crossing numbers were significantly stronger than knots with higher numbers – which is exactly the opposite of what is observed with traditional, nylon fishing line.

By examining the broken strands using optical and electron microscopes, the physicists discovered that torus knots with low crossing numbers broke due to the bending of the strand at one edge of the knot. However, torus knots with high crossing numbers broke deep inside the knot as a result of the twisting of the strand.

Uehara told Physics Web that the results suggest that nylon is more flexible and resistant to damage by twisting than PVDF, but that more experimental work is needed to understand the processes involved.

Preliminary tests on a different type of knot in PVDF (called a “twist knot”) suggest that strength increases with crossing number in that knot – the opposite of what was seen for PVDF torus knots. Uehara believes that this occurs because there is actually much less twisting in a twist knot.