When you walk, one set of muscles drives your legs forward, while another does “negative work” by pulling in the opposite direction to control your stride. Now, researchers in Canada and the US have built a device that can convert this negative work into electricity. They claim that the device, which straps onto the leg around the knee, can generate 5 W of electricity — enough to power several mobile phones or even an artificial limb.

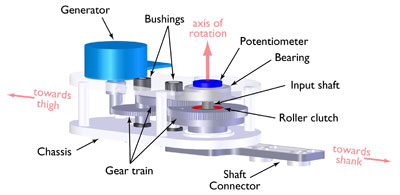

The electricity-generating knee brace has been designed and built by Max Donelan and colleagues at Simon Fraser University in British Columbia along with researchers at the Universities of Pittsburgh and Michigan (Science). It consists of a standard knee brace rigged with a generator and clutch system.

Rotary motion

The brace has a flexible joint that allows the wearer to walk and the rotary motion at the joint drives a set of gears, which are connected to an electrical generator.

The clutch can be adjusted so that energy is only harvested towards the end of a stride, when the body does negative work to stop the leg swinging forward just before it touches the ground. According to Donelan, this allowed the team to overcome a major challenge in harvesting negative work — how to ensure that the device helps the body slow down a limb without otherwise hindering its motion.

The brace can also work in a second mode in which energy is harvested throughout the stride.

1.5-kg device

The team tested the 1.5-kg device by strapping it on six volunteers who then walked on a treadmill. The electrical output of the brace was monitored along with the amount of oxygen inhaled by the subjects — which is a measure of the metabolic energy expended while walking.

When harvesting just negative work, the brace generated nearly 5 W of power while the wearer had to expend an additional 5 W — making it a very efficient way of converting muscle power into electrical power. By contrast, a hand-cranked generator requires more than 6 W of human effort for every Watt of electricity.

When the brace was used in the second mode, subjects were able to generate electricity at 7 W, while expending an additional 18 W of metabolic power. The maximum electrical power that could be generated was about 13 W.

Donelan told physicsworld.com that a 5–18 W increase in effort while walking is not significant — most people expend about 300 W walking without the device.

A major problem with the brace, however, is that just walking with the clutch permanently disengaged and generating no electricity costs about 60 W.

High cost of carrying

Walter Herzog, who is an expert in biomechanics at the University of Calgary, told physicsworld.com that when the relatively high energy cost of carrying the device is considered, the brace is really no more efficient than other schemes for generating electricity from walking. These include shoes with special soles that generate electricity when compressed and backpacks with oscillating weights connected to a generator.

Donelan counters that the brace was designed to make the experiments easier — not to minimize the effort required to wear it. He told physicsworld.com that the team are currently working a next-generation device that will be about half the weight of the original brace and that much of the weight will be shifted to a more comfortable location higher up the leg of the wearer. This, he claimed, could reduce the extra effort required to wear the brace to as little as 15 W.

As well as powering portable electronic devices — something that could be very important to soldiers and others who spend long periods of time in remote areas — both Donelan and Herzog agree that the most likely application of the brace is to power artificial limbs and other prosthetic medical devices, reducing the number of heavy batteries that users would have to carry around.

Donelan and colleagues have formed a company called Bionic Power that now aims to develop braces for the military and medical markets.