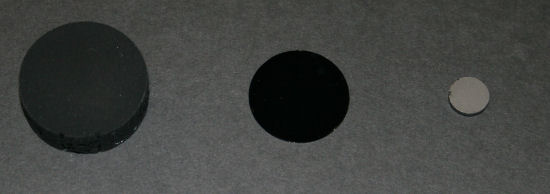

Researchers in the US claim to have made the world’s darkest material using arrays of carbon nanotubes.The new material reflects just 0.045% of light incident upon it, making it blacker than the previous record holder — a nickel and phosphorous alloy that reflected about 0.16% of incident light. The material could be used to boost the efficiency of solar panels.

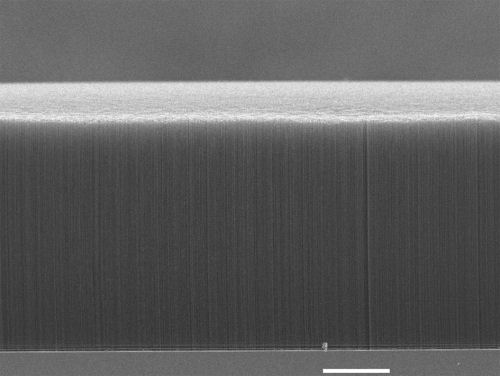

A carbon nanotube can be considered as a single sheet of graphite that has been rolled up into a tube. The material — which was created by researchers at Rensselaer Polytechnic Institute and Rice University — is a thin coating comprised of low-density arrays of vertically-aligned carbon nanotubes.

“When we measured how dark the material was, the final numbers were more dramatic than we thought,” said Pulickel Ajayan of Rice University.

Extreme diluteness

The light absorption stems from a combination of the material’s structural properties. “First, the material is very porous and has a material filling fraction of 3–5%,” explained physicist Shawn-Yu Lin of Rensselaer. “This extreme diluteness makes it very non-reflective.”

Another factor is the random surface, which diffracts light and further reduces reflectance. “In addition, the material is made of extremely long carbon nanotubes, 8–10 nm in diameter and 500–1000 µm long,” said Lin. “The carbon material and the long structure enable a total absorption of the light that gets in.” The reflectance of the nanotube array is said to be two orders of magnitude lower than that of glassy carbon, despite both samples being made of the same element.

The material’s properties could be useful in applications such as solar panel manufacture. “Thermalphotovoltaic (TPV) conversion that requires a complete absorption of light from all angles, at both polarizations and for all wavelengths of interest, could be a possible application,” commented Lin.

As the nanotube array is very porous, it is not durable against mechanical force. “The material would need to be covered by some form of thin coating, but this would not limit the TPV application, for example,” observed Lin. “We have tested the material’s thermal stability by heating it up to 1500 K, and it maintained its structural integrity.”

The team now plans to carry out further experiments on the material. “We would like to extend our measurements from visible wavelengths to infrared and microwave regimes, to check the universality of the phenomenon,” said Lin. “We also want to develop a comprehensive theory to understand our discovery, and explore the absolute lower limit of reflectance possible using our approach.”