Graphene is the strongest material in the world, according to new experiments done by researchers at Columbia University in the US. The secret to the material’s extraordinary strength, says the team, lies in the robustness of the covalent carbon-carbon bond and the fact that the graphene monolayers tested were defect-free.

Since “wonder material” graphene – sheets of carbon just one atom thick – was discovered in 2004, it has been shown to be an extremely good electrical conductor; a semiconductor that can be used to create transistors; and a very strong material. But now, Columbia University’s James Hone, Jeffrey Kysar, Changgu Lee and Xiaoding Wei have shown that it is the strongest material ever (Science 321 385).

The researchers measured the intrinsic strength of the material — that is the maximum stress that a pristine (or defect-free) material can withstand just before all the atoms in a given cross-section are pulled apart at the same time. This was found to be 42 Nm–1 and represents the intrinsic strength of a defect-free sheet.

Essentially all materials contain defects, such as microscopic cracks or scratches, which are “weaker” than surrounding material. As a result, the breaking stress of a macroscopic material depends mainly upon the number and sizes of defects it contains, rather than its intrinsic strength.

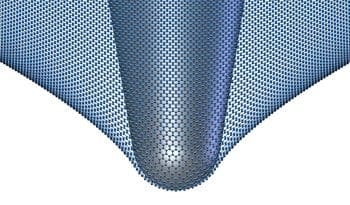

The researchers began by exfoliating individual atomic layers of graphene from a graphite source using transparent sticky tape — the most popular way of preparing monolayer graphene. Next, they placed the graphene flakes over a series of holes on a silicon wafer – rather like placing plastic cling film over a tiny “muffin tin”. Each hole measured either 1.0 or 1.5 µm across.

Tiny drums

“Each graphene film is like a small drum,” explained Kysar, “except that the drumhead is only one atomic layer thick.” The team then indented the graphene film using an atomic force microscope with a diamond tip that has a radius of about 20 nm. It was necessary to use a diamond tip because conventional silicon tips would break before the graphene breaks.

The force-displacement response of the monolayer graphene films allowed the scientists to determine the elastic properties of the graphene film. The force at which the film breaks and the statistical distribution of the breaking force of many films allowed them to calculate the intrinsic strength of graphene.

“The stiffness of graphene is literally ‘off the chart’ when compared to other classes of material,” Hone told physicsworld.com. “This is thanks to both the covalent carbon-carbon bonds in graphene as well as the absence of any defects in the highest stressed portion of the graphene films.”

The graphene monolayers used in the experiments are defect-free because they are so small, something that precludes the existence of flaws — a condition that cannot be satisfied in macroscopic materials. Given the known robustness of the covalent carbon-carbon bond (that also gives carbon fibres used in high-performance composites their remarkable stiffness and strength), it is not unreasonable to claim that pristine graphene is the strongest material,” said Kysar.

Upper bound on strength

The new result will also serve as an experimental ‘benchmark’ James Hone, Columbia University

“The intrinsic strength of graphene can be considered as an ‘upper bound’ for the strength of materials — rather like diamond is for hardness — that could serve as a goal for engineers who design materials,” added Hone. “The new result will also serve as an experimental ‘benchmark’ to validate various theories and computer models that predict the elastic properties of materials at very high strains.”

“To put things in perspective: if a sheet of cling film (which typically has a thickness of around 100 µm) were to have the same strength as pristine graphene, it would require a force of over 20,000 N to puncture it with a pencil,” he explained. “That is the force exerted by a mass of 2000 kg, or a large car!”

The team is now performing more experiments to determine the friction properties of freestanding monolayer graphene, as well as quantifying the van der Waals forces between the graphene and underlying substrates.