A water-purifying filter made from normal cotton coated in nanostructures has been developed by researchers at Stanford University in the US. They say that the device, which works by killing bacteria with electrical impulses, is 80,000 times faster than conventional filters and could become a useful tool for remote communities in the developing world. But the breakthrough has already been met with a degree of scepticism by other scientists in the field, who question elements of the design.

Instead of physically trapping bacteria like most existing filters do, the new filter lets them flow on through with the water. But by the time the harmful pathogens have passed into a water container they have been exposed to an electric field, generated by the coated cotton, which kills large swathes of them.

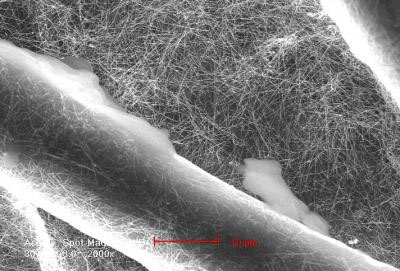

To develop their nano coating, Yi Cui and his Stanford colleagues built on recent work investigating the use of silver nanoparticles for antibacterial treatment of a variety of substrates, including cloth and medical devices. Instead of particles, however, Cui’s team use silver nanowires ranging from 40 to 90 nm and combine them with carbon nanotubes of similar dimensions, which are exceptionally strong and good electrical conductors.

“We got it at Wal-mart”

The nanowires and nanotubes are prepared separately and then added to simple dyes – the nanotubes in a water-based dye and the nanowires in an alcohol-based dye. The dyes are then applied to cotton, which was chosen as the foundation material because it is cheap as well as being relatively strong and chemically robust. “We got it at Wal-mart,” explains Cui. Adding, “The amount of silver used for the nanowires was so small that the cost was negligible.”

In lab tests, a piece if fabric comprising several layers of coated cotton was connected to an electrical power source set to 20 V. Then, water containing a common strain of E. Coli was poured onto the fabric and allowed to pass through at a rate of 10,000 L/h/m2. With this set up, the researchers found that they could rid the water of 98% of bacteria at a rate that was 80,000 times faster than was possible with existing filters.

“The technique is interesting because it uses widely available cotton fabric as the basis for the filter and it relies on an electric current rather than mesh size to remove the pathogen hazard,” says Andrew Scott, a director at Practical Action, a charity that promotes technology for development. Scott is concerned, however, that the filter requires a source of electricity, which is not always available in remote communities.

Energy troubles

The issue of energy requirements also troubles Mark Shannon, a water engineer at the University of Illinois in the US. “[The researchers] reported about 2 logs reduction of pathogens, which is a “modest” reduction – typically you want more than 4 logs,” he says. “So the amount of energy used to kill off the pathogens per unit volume of water is likely much greater than that for boiling water”.

The Stanford team acknowledge that further development is needed to improve the purification process. “With one filter, we can kill 98% of the bacteria,” says Cui. “For drinking water, you don’t want any live bacteria in the water, so we will have to use multiple filter stages.

“It will also be important to investigate how well the filter retains the nanomaterials we use, so that we can be sure the filtered water does not contain silver nanowires and carbon nanotubes,” he says.

Peter Dobson, an engineer scientist at the University of Oxford, agrees that the idea of an electrically controlled membrane is a “worthy and interesting idea” and he is impressed by the use of cotton as an inexpensive base material. However, he is frustrated by the lack of experimental detail in the related research paper. “The actual experimental set-up is very poorly described, and the manner in which the filter has been constructed is not clear, and it is also not clear how the electrical connections were made.

This research is described in a paper in Nano Letters.