Researchers in the US have made the first high-frequency AC “supercapacitors” containing graphene electrodes. The devices, which are much smaller than conventional capacitors, could be used in applications like computer processing units and other tiny integrated circuits.

Capacitors are devices that store electric charge. “Supercapacitors”, more accurately known as electric double-layer capacitors (DLCs) or electrochemical capacitors, can store much more charge thanks to the double layer formed at an electrolyte-electrode interface when voltage is applied.

Commercial DLCs are extremely powerful when compared with batteries but they are essentially DC devices – that is, they take several seconds to fully charge and then several seconds to fully discharge again. They operate efficiently at frequencies below about 0.05 Hz and are therefore good for applications like hybrid vehicles, which can take up to 10 seconds to charge (when braking) and 10 seconds to discharge (when accelerating). However, at higher frequencies, they become much less efficient and start to behave like resistors rather than capacitors. This is because the devices usually contain porous electrodes made from a high-surface-area conductive material, such as activated carbon, and the pores increase the resistance of devices.

Now, John R Miller and colleagues of JME Inc. in Shaker Heights and Case Western Reserve University, Cleveland, both in Ohio, have overcome this problem by developing the first DLC that contains vertically oriented high-surface-area graphene electrodes that aren’t porous at all. The device pushes the operating frequency of an electric double layer capacitor to well beyond 5000 Hz, which is a factor of 105 better than commercial DLCs. What’s more, it is six times smaller than low-voltage aluminium electrolytic capacitors and can be charged and discharged at high efficiency in times much shorter than 1 ms.

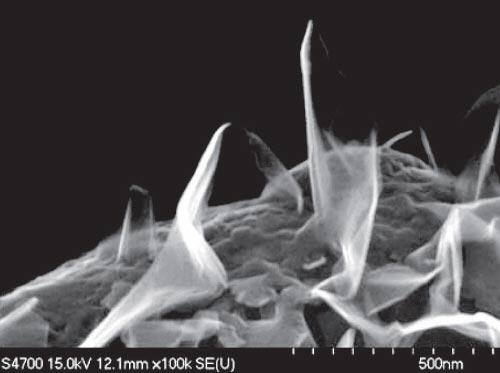

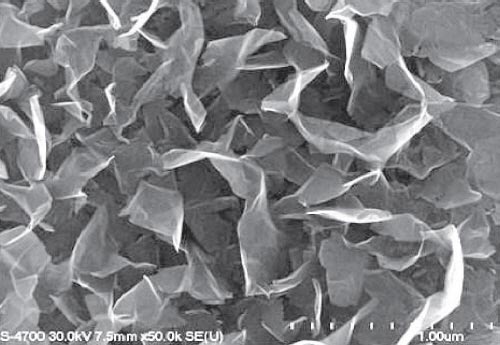

The researchers grew the graphene – 2D sheets of carbon just one atom thick – on a metal using a plasma-assisted chemical vapour deposition process.

Such vertically oriented graphene sheets are ideal in terms of structure for high-frequency DLC electrode applications, says the team. They have many edge planes that can provide between 50 and 70 µF/cm2 of capacitance compared with basal planes, which only provide 3 µF/cm2. These charge-storage edge planes are highly exposed and can thus be accessed directly, which means that charge can be stored over precise areas rather than being dispersed over larger regions. And last but not least, the nanosheet “stacked” structure ensures that pores are reduced – so minimizing resistance – and the sheets themselves are highly conducting.

“The bottom line is that these devices could lead to smaller higher-frequency capacitors for applications in low-voltage systems like CPUs and similar integrated circuits,” Miller said.

The research might also enable new classes of electronic circuit that use the much higher levels of capacitance that these devices make available, he adds.

The team, which includes scientists from the College of William and Mary in Williamsburg and the Defense Advanced Research Projects Agency, both in Virginia, now plans to improve how the graphene electrode material is grown and optimize the design of the capacitive devices.

The work was published in Science.