A miniature version of a well-known plumbing nuisance could be having a more deadly effect on industrial machinery than we first thought. That is according to researchers in the US who have characterized something known as the “water hammer” effect and how it can enable water droplets to penetrate surfaces.

People living in older houses often complain about the water hammer where pounding noises can be heard emanating from pipes. It is caused when a valve is suddenly opened triggering a pressure wave to shoot through the pipe, which can even cause pipes to rupture.

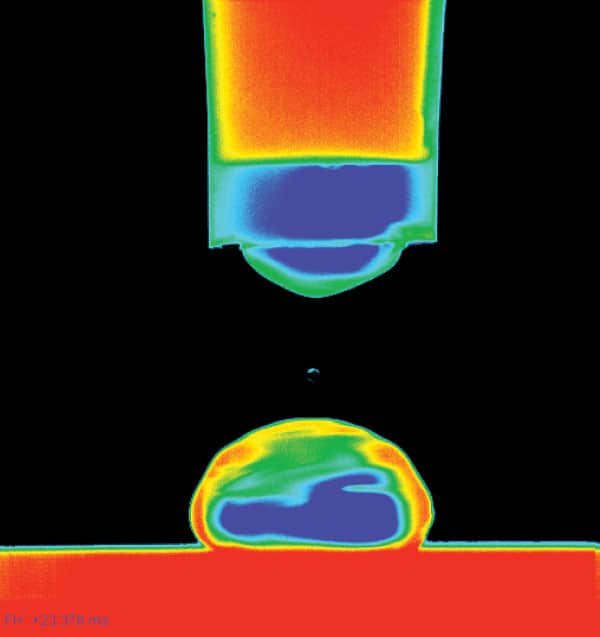

On a much smaller scale, this effect is seen within individual water droplets – as they land on surfaces, a pressure wave passes through the droplet, causing it to wobble and deform. This phenomenon can be a hindrance to industry because it can reduce the efficiency of machinery and cause erosion to surfaces.

Beware the Wenzel state

It is of particular significance to the operation of steam turbines, which account for roughly half of all the electricity generated on the planet. The killer blow to the turbine blades occurs when water droplets make a transition to a state known as the “Wenzel state” where they can penetrate beneath surfaces, causing irreparable damage.

“I have seen blades that have become aerodynamically compromised within one year and completely defunct within two,” says Kripa Varanasi, one of the researchers at Massachusetts Institute of Technology (MIT), who previously worked with the turbine maker General Electric.

Varanasi and his colleagues have now investigated the water hammer effect in droplets in unprecedented detail to determine what governs its dynamics. They conducted a series of experiments by carefully depositing water droplets of varying sizes onto a number of silicon surfaces that were patterned in different ways. Reporting their findings in Physical Review Letters, the researchers arrived at a surprising result.

While previous studies had assumed that larger droplets were less likely to penetrate a surface, Kripa’s team found that even relatively large droplets of 75 µL could penetrate beneath surfaces by making the transition to the Wenzel state. “It’s counterintuitive that such a gentle collision could have such a large impact,” Varanasi told physicsworld.com.

Busy surfaces are good

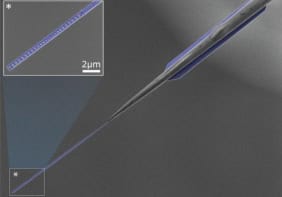

Instead, the researchers found that the water hammer effect is powerful enough to enable droplets to grip surfaces and penetrate beneath. The key to resisting this wetting, they say, is to increase the density of surface features, which in their experiment took the form of tiny silicon posts. When posts were spaced at 40 µm intervals, only really small droplets of less than 0.03 µL could penetrate the surface.

“This work is very interesting because it identifies a new route to the undesirable Wenzel state, in which water penetrates a textured surface and sticks to it,” says Chuan-Hua Chen, a fluid mechanics researcher at Duke University, North Carolina.

Varanasi and his team are now developing their work by investigating economical ways of patterning surfaces such as the chrome steel used in steam turbines and the nickel alloys used in higher-temperature environments such as the engines of aircraft. “If we could design surfaces that can prevent droplets from building up on blades, we could improve the efficiency of these machines by 5–8%,” says Varanasi.

The sort of designs, he says, might involve self-assembly techniques where nanoparticles are distributed over surfaces, or developing new nanoporous structures. The designs may also take inspiration from textured surfaces in nature such as lotus leaves and the skins of geckos, which are known for being exceptionally water-repellent.