Researchers in South Korea are the first to make a bendable digital memory that can store data without constant power. Such memories could find applications in electronic paper for more comfortable reading and in wearable computers, which could be used in medical monitoring and treatment.

A memristor “remembers” the amount of charge that has flowed through it, with the information being stored in terms of the device’s resistance. While the concept of the memristor was first proposed in 1971, it was not until 2008 that the first practical device was made.

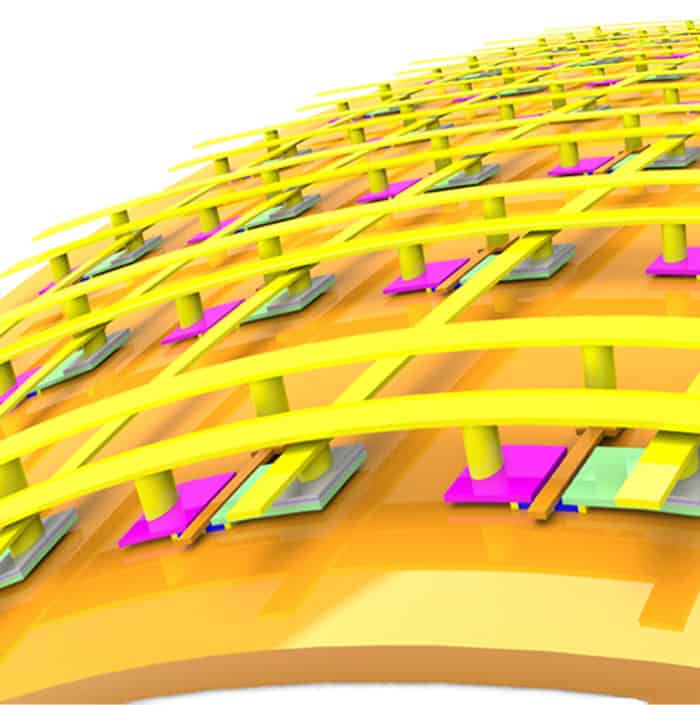

Since then, several research groups have explored the development of flexible memories by placing memristors in cross-point configurations. Two arrays of parallel metal lines are placed one on top of the other in a grid; where the lines cross, they are connected with a memristor. By running current along the two wires that cross a particular memristor, the researchers can – in theory – read, write or erase information encoded in its resistive state.

Enriched with oxygen

Keon Jae Lee of the Korea Advanced Institute of Science and Technology (KAIST) and colleagues made their memristors from amorphous titanium dioxide with aluminium electrodes at the top and bottom. The team deposited titanium dioxide in atom-thick layers between the electrodes, leaving the interface at the top electrode enriched with extra oxygen ions because of oxygen’s affinity for aluminium.

When a negative voltage is applied to the top electrode, negative ions are pushed into the titanium dioxide, thus reducing the material’s electrical resistance. This low-resistivity state is the equivalent of a binary “1”, and it endures for at least 2.7 hours even when the voltage is switched off.

Switching the polarity of the electrodes causes the positive top electrode to draw the oxygen back out. This returns the memristor to the high-resistance “0” state. The state of the memristor can be read-out by applying a small, –0.5 V, read voltage and then measuring the current. The current that runs through the memristor in its low-resistance state is 50 times higher than if it ran through a high-resistance memristor.

Simple, but flawed

Unfortunately, this simple set-up has a major flaw. A read current that is meant to probe a high-resistance memristor would instead prefer to travel through its lower-resistance neighbours – and it can. This makes the resistance of the read memristor look smaller than it really is. As long as these “sneak paths” exist, the memory cannot be accurately read, written or erased, says KAIST’s Seungjun Kim. To cut off the sneak paths, the team paired each memristor with a flexible silicon transistor, which prevents current from flowing through the memristor unless it is selected for the operation.

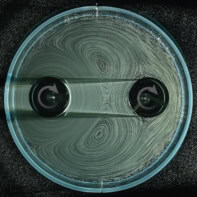

The team made arrays of 64 memristor–transistor bits, eight to a side on a flexible plastic base. To demonstrate the memory’s pliability, the team gradually bent it from a curvature radius of 28.6 mm to 8.4 mm. The researchers measured the high- and low-resistive states along the way, reporting no significant change to either state. To test the material for fatigue, the team flexed an array on a 2.8 cm-long piece of plastic so that its edges were 1.8 cm apart. The team bent and relaxed the memory 1000 times, observing little alteration in performance.

“Crucial step”

Wei Lu at the University of Michigan in Ann Arbor, who was not involved in the research, calls the work a “crucial step” towards flexible memory devices because it makes the jump from single cells to small arrays. However, he points out that the team only tested 2 × 2 subsets of their 8 × 8 arrays, and that the researchers will need to prove the technology in larger arrays to show that it can be scaled up. He also notes that the 64-bit memory covers a “whopping” square centimetre. “For comparison, modern solid-state memories are more than 100 million times denser,” he says.

The team is already investigating options for more compact arrays, combining a diode and unipolar resistor for each bit of its next flexible memory. In addition to taking up about a third less space than memristor–transistor bits, Lee suspects these will be easier to mass produce.

The work is described in Nano Letters.