Scientists in the US have used a common virus to produce materials that resemble skin and bone. In addition to providing new insights into how such materials develop in the natural world, the work also brings synthetic production of tissue in the laboratory closer to reality.

In nature, completely different materials are often assembled from many copies of the same basic molecule such as a protein. Collagen type I, for instance, is a protein molecule that can combine with various other chemicals to form skin, bone or even eye tissue. This process is called self-templating because individual molecules are not assembled according to an external template. Instead, thermodynamic factors such as temperature and solution concentration are controlled to ensure that the desired configuration is the one that is energetically favoured.

Scientists are keen to mimic these processes – but the extreme sensitivity to thermodynamic factors that drives self-templating makes such molecules extremely difficult to work with in the lab. Indeed, it remains a mystery how nature can achieve the precision control that has so far eluded the laboratory chemist.

Going viral

An elegant solution to this problem is to use the M13 phage as a base unit, rather than a molecule such as collagen. M13 is a virus that attacks E. coli bacteria but is harmless to humans. It is relatively easy to grow and control in the lab because its protein coat can be manipulated by genetic engineering – a trick discovered by Seung-Wuk Lee, Angela Belcher and colleagues at the University of Texas at Austin in 2002.

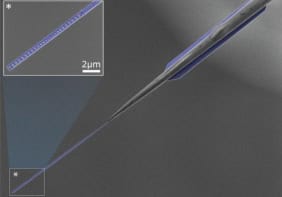

In this latest work, researchers led by Lee, now at the University of California, Berkeley, and the Lawrence Berkeley National Laboratory, have looked at the physical conditions under which different molecular structures would form from genetically modified M13 viruses. They started with solid plates immersed in a virus-rich salt solution and carefully drew the plates out of the solution, allowing the salt solution to evaporate, leaving a thin film of viruses on the plates.

As the concentration of the virus solution was increased, so too did the complexity of the patterns on the plates. At concentrations of 0.1–0.2 mg/ml, the researchers saw a simple alternating pattern of ridges and grooves. However, at a concentration of 6 mg/ml, the patterns on the plates showed much more complex, long-range order that the researchers say is reminiscent of dried ramen noodles.

Pulling noodles

The researchers also investigated the effect of extraction speed. They found that the optical properties of these “ramen-noodle-like” structures varied quite distinctly depending on how fast the plate was withdrawn from the solution. Increasing the pulling speed from 50 µm/min to 80 µm/min reduced the peak reflected wavelength of one film from 490 nm to 388 nm. The scientists point out that natural materials with such wavelengths are what give some bird feathers and beetle shells dazzling structural colour.

The team produced bulk 3D structures by using their films as substrates on which to grow cells. The cells grew differently on different films. On one substrate, the scientists even managed to grow mineralized tissue similar to tooth enamel.

Lee underlines that his group does not claim to have replicated the processes used to produce these materials in the natural world – something that is still poorly understood. “We believe the actual process of how nature produces these materials is very far from our process, but the important thing is that we begin to test the importance of the kinetic factors and then begin to engineer, and very closely mimic, the structures that nature produces,” he says.

Belcher, who now works at the Massachusetts Institute of Technology and was not involved in the recent work, is impressed. “I think the most exciting aspect of this work is the ability to use a genetically tunable single molecular building block to finely control the self-templating and assembly of materials over multiple levels of organization. The researchers then exploit this ordering for a diverse set of applications. This system should be readily adapted to other applications and materials,” he says.

The research is described in Nature.