An international team of researchers led by Ray Baughman of the University of Texas at Dallas has developed a new type of artificial muscle made from a “yarn” of twisted carbon-nanotube threads infused with wax. The new actuator structures are different from previously made devices in that they do not need an external electrolyte to function. The muscles can lift more than 100,000 times their own weight, can contract and expand extremely quickly and can operate over a wide temperature range. Such properties could make them ideal for use in a range of future applications, such as humanoid robots, intelligent textiles and advanced rotary motors.

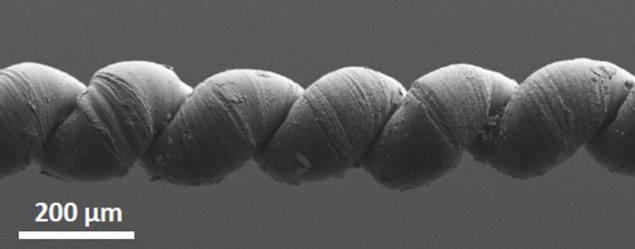

The team made the artificial muscles by first growing a vertically aligned forest of carbon nanotubes. These are hollow cylinders of rolled-up carbon sheets with walls as thin as a single atom. The researchers then drew a thin sheet of nanotube bundles from the forest and twisted this sheet to make a yarn containing helices of intertwined carbon nanotubes. Next, they infused the yarn with molten paraffin wax.

Each end of a thread was then connected to a power supply. When a voltage is applied, the wax heats up and expands. The pressure subsequently produced by this expansion causes the twisted yarn to contract and to partially unwind, which creates a rotating action similar to that seen when stretching a helical spring. The yarn rotates in the opposite direction as the wax cools. Carbon nanotubes are ideal for making such yarns – the sheets are nearly as light as air (they have a density of around just 1.5 mg/cm3) but are stronger than steel, with a specific strength that can reach 560 MPa cm3/g.

Simplified design

Previous artificial-muscle designs work in a similar way but they rely on the nanotubes being immersed in a liquid electrolyte. The use of wax effectively dispenses with the need for such an external conducting liquid, so simplifying the muscle design greatly, explains Baughman.

“The torsional action of the thread can be used to rotate an attached paddle to an average speed of 11,500 revolutions per minute for more than two million reversible cycles,” he says. “The wax-infused nanothreads can also lift more than 100,000 times their own weight and can generate 85 times more mechanical power during contraction than the same size natural muscle. This equates to them being able to lift weights 200 times heavier than is possible for natural muscle of the same diameter.”

Good even without wax

Coiling the nanotube thread increases its thermal expansion coefficient by 10 times, even without the wax filling, he adds. “This thermal expansion is negative, which means that the unfilled yarn contracts as it is heated. Indeed, heating the yarn in an inert atmosphere from room temperature to about 2500 °C (a temperature much higher than the melting point of steel) provides more than 7% contraction when lifting heavy loads – something that has never been seen before for such high-work-capacity actuators.”

According to the researchers, this high thermal expansion for the coiled yarns means that they could be ideal for use in intelligent textiles that would happily function between –50 and 2500 °C. Such proposed textiles would be able to adapt to the needs of the wearer, providing protection in cold conditions, for example, by becoming less porous and cooling the wearer down by becoming more so. Taking this idea a step further might entail incorporating the yarn muscles into sportswear and perhaps even fire-fighter clothing. The artificial muscles might also be used in microfluidic circuits as pumps and for regulating valves, and even in novel applications such as window blinds that open and close in response to ambient temperatures.

“Other possible applications include medial catheters for minimally invasive surgery, nanoactuators and motors in future micromachines, zoom lenses for digital cameras, humanoid robotics, prostheses and exoskeletons,” Baughman says.

Early commercialization possible

Such applications may not just be distant dreams because the researchers have already succeeded in producing kilometre lengths of their yarns. “Since small actuators only require centimetre lengths of thread, this suggests that early commercialization of this material should not be a problem,” says Baughman. “What will be more difficult, however, is to upscale the single-thread actuators to larger ones in which hundreds or thousands of individual muscles operate in parallel.”

The team, which includes scientists from Australia, China, South Korea, Canada and Brazil, is now busy demonstrating new applications for its single-yarn muscles. It is also trying to upscale to large muscles comprising fibre arrays such as those found in natural skeletal muscle.

The current work is detailed in Science.