Researchers at Columbia University in the US have built the smallest frequency-modulated (FM) radio transmitter ever. Based on a graphene nanomechanical system (NEMS), the device oscillates at a frequency of 100 MHz. It could find use in a variety of applications, including sensing tiny masses and on-chip signal processing. It also represents an important first step towards the development of advanced wireless technology and the design of ultrathin mobile phones, says team co-leader James Hone.

“Our device is much smaller than any other radio-signal source ever made and, importantly, can be put on the same chip that is used for data processing,” he explains.

Graphene is a sheet of carbon atoms arranged in a honeycomb-like lattice that is just one atom thick. Since its discovery in 2004, this “wonder material” has continued to amaze scientists with its growing list of unique electronic and mechanical properties, which include high electrical conductivity and exceptional strength. Indeed, some researchers believe that graphene might even replace silicon as the electronic industry’s material of choice in the future.

Ideal for making NEMS

Graphene is ideal for making NEMS – which are scaled-down versions of the microelectromechanical systems (MEMS) that are routinely employed in vibration-sensing applications. The new device made by Hone and colleagues is a NEMS version of a common electronic component known as a voltage-controlled oscillator (VCO) and generates a frequency-modulated (FM) signal of about 100 MHz. This frequency lies exactly in the middle of the FM radio band (87.7–108 MHz) and the researchers say that they have already succeeded in using low-frequency music signals to modulate the 100 MHz carrier signal from their graphene NEMS and recover the signals again using an ordinary FM receiver.

While graphene NEMS might not replace conventional radio transmitters yet, they will certainly be used in many other wireless signal-processing applications. Although electrical circuits have been continuously shrinking over the last few decades (as described by Moore’s law), there are still some types of devices – especially those involved in creating and processing radio-frequency (RF) signals – that are notoriously difficult to miniaturize, explains team co-leader Kenneth Shepard. Called off-chip components because they cannot be integrated with miniaturized devices, they require a lot of space and electrical power, and their frequency cannot be easily tuned.

Graphene NEMS offer a solution to this problem because they are very small – the active area is only a few microns across – and they can potentially be integrated directly onto conventional CMOS chips. Most importantly, it is easy to tune their frequency thanks to graphene’s exceptional strength.

Adjusting the tension

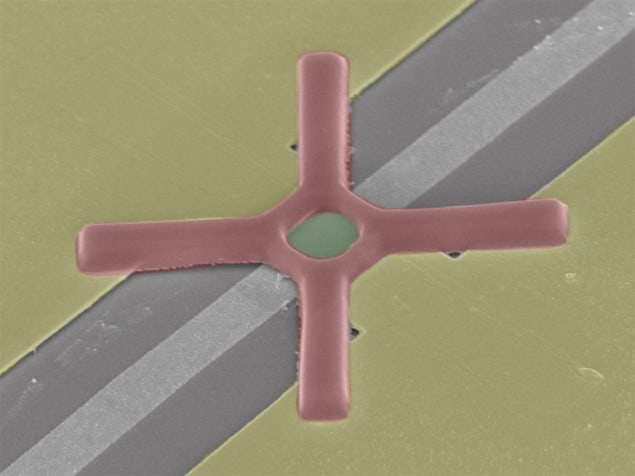

The Columbia researchers made their devices by contacting graphene sheets to source and drain electrodes and freely suspending the sheets over metal gates. In this configuration, the graphene functions like the skin of a drum. A DC gate voltage pulls the graphene down towards the gate and this adjusts the tension and, therefore, the mechanical resonance frequency, explains Hone. A radio-frequency signal on the gate drives sheet vibrations. “Finally, we apply a DC bias across the graphene and when the graphene vibrates it acts as a transistor whose gate capacitance is constantly changing – and it is this that creates an RF source–drain current,” he says.

The team studied the vibrational properties of the device at room temperature in a vacuum chamber. “To make an oscillator, we first adjust the signal gain to just above unity (using a variable amplifier) and the phase to zero (using a phase shifter) at the resonance frequency,” says Hone. “We then connect the output to the gate. This creates a closed loop that amplifies random thermal vibrations and makes the device oscillate.”

The researchers say they are now busy looking at how to put their devices directly onto integrated circuits that already contain all the necessary drive and readout circuitry. They also hope to improve the performance of their oscillators and reduce device noise.

The oscillator is described in Nature Nanotechnology.

- This article first appeared on nanotechweb.org