Researchers in Australia have invented a new kind of optical lens that could be combined with a smartphone camera to create a microscope for diagnosing skin cancer or identifying agricultural pests. The lens, which is simple to make and costs almost nothing to produce, consists of droplets of polydimethylsiloxane (PDMS) gel that have been hardened in an oven. The lens can be made without anyone having to grind or mould it, which normally requires specialized equipment and skills.

The lens has been developed by Steve Lee and colleagues at the Australian National University, who came up with the idea by accident. While making PDMS using conventional moulds, Lee noticed that droplets of spilled gel that had hardened overnight in the oven were lens-shaped. He showed them to a friend who is a medical doctor, who pointed out that there is a demand for medical-imaging lenses that are simple and cheap to make.

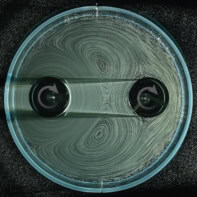

Inspired by the discovery and its potential applications, Lee and colleagues devised a fabrication process that begins with a small droplet of the gel being placed onto a flat substrate, where it spreads out to create a flat base. After baking this base in an oven at 70 °C, a second droplet is then placed on top, and the substrate is flipped over so that the new droplet is clinging onto the underside of the base. The force of gravity on the drop ensures that it forms a perfect parabolic shape and the sample is then baked again to harden the lens. “It’s very easy to do,” says Lee. “I think anyone could do it at home.”

DIY lens

The team has used its technique to make lenses that are a few millimetres thick and have magnifications of up to ×160. The lenses can resolve structures as small as 4 μm and, according to Lee, they can therefore be used to image individual biological cells. While this magnification is not as high as commercial microscopes, Lee points out that it can be achieved at a fraction of the cost. “We’re quite surprised at the magnification enhancement using such a simple process,” he says.

To show that the lenses can be used for practical medical applications, the team has created a simple “clip-on” device that converts a smartphone into a “dermascope”: a medical device that is used to diagnose skin cancers and that can cost $500 or more. Built for about $2 using a 3D printer, the device integrates a lens, battery and a light-emitting diode (LED) into an imaging module that can be attached to a smartphone. The device can then be pointed at a patient’s skin to take images of, say, a skin lesion.

Access to expert analysis

Once the image of a lesion has been acquired, it can then be transmitted across a mobile-phone network to an expert for analysis, which would be particularly useful for health workers in remote areas. A similar approach could also be used by farmers to take images of microscopic pests on crops before sending them to an agricultural scientist for identification. Other applications include implanting such lenses into live animals to observe the development of living cells, which could give us a better understanding of how diseases progress. Such experiments would be much cheaper to carry out if low-cost disposable lenses were available.

Beyond science and commerce, Lee believes that the microscope could also be used in schools and even by hobbyists. “The smartphone creates a perfect platform,” he says. “By 2018 or so there will be about 1.7 billion smartphones worldwide, so what we are doing is distributing microscopy to the masses.” However, not all optical-imaging researchers are as enthusiastic as Lee, with one expert telling physicsworld.com that the technique does not offer a way of controlling the curvature of the lens – something that is important for making useful lenses.

The team is also limited to making lenses with diameters less than about 1.3 cm, but is now trying to make lenses as large as 5 cm. The team is also seeking to improve the lenses’ optical properties.

The lens is described in Biomedical Optics Express.