A solid-state supercapacitor that works under great stresses and vibrations has been developed by researchers from the US. Unlike traditional supercapacitors, the new design does not delaminate under stress and could lead to a variety of practical applications, from more-efficient devices to renewable-energy storage.

Unlike batteries – which work through chemical reactions – supercapacitors store energy in the form of electrically charged ions, which are assembled on the surfaces of porous electrodes. Supercapacitors also have numerous benefits: they can charge and discharge in minutes – unlike batteries, which take hours – and have a much longer lifespan, lasting for millions of cycles rather than thousands. Their drawback, however, comes in their reduced storage capacity – to hold a given charge, most supercapacitors need to be much larger and heavier than an equivalent lithium-ion battery.

Heavy-weight storage

One idea to overcome this limitation lies in creating supercapacitors that act as both energy storage and structural support. By doubling up the otherwise “dead weight” of structural materials, the rapid-charging, long-lasting nature of supercapacitors could be utilized without needing an internally distinct power source. This concept of a “structural supercapacitor” could have many potential applications – for example, a laptop where the case acts as a battery, renewable energy stored within the walls of a house, or even a rapidly charging electric car that stores power in its own chassis. To be used as such a structural device, the supercapacitor would need to work under considerable stresses and vibrations. Traditional supercapacitors are ill-suited to this task – being layered, their electrodes and electrolytes are prone to separate when such forces are applied.

Strong bonds

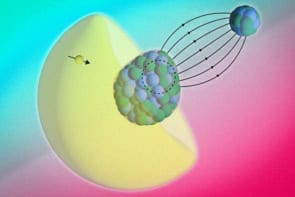

To overcome this problem, a team of researchers, led by Cary Pint from Vanderbilt University in Tennessee, has engineered a supercapacitor with better-integrated layers. The design features electrodes made from silicon wafers, the inner sides of which are electrochemically etched to create a surface covered in nano-sized pores. These are then coated with a protective, ultra-thin layer of carbon, before being vacuum-squeezed together around an ion-conducting polymer. This electrolyte seeps into the silicon’s nanopores, setting into a strong mechanical bond, which does not come apart easily.

When tested, the researchers found that the design offers an energy density of up to 10 W h/kg and operates perfectly, even under stresses of 44 psi and vibrational accelerations over 80 g – the latter of which is greater than the forces acting within working jet engines. While designs for structural supercapacitors have been reported previously (mostly based around the use of carbon fibres) the team’s design is capable of 3 to 4 orders of magnitude more charge storage – comparable, in fact, with (regular) commercial supercapacitors. Pint points out that the design showed that its “performance is not compromised while we operate the device under compression, shearing, tensile stretching, high-amplitude vibrations, and impact forces”. He adds that the manufacturing process is simpler than in traditional supercapacitors and involves minimal cost, with both the component materials and the production process being relatively cheap. Furthermore, the constituent parts are both bio-friendly and non-flammable, thereby removing some of the safety concerns traditionally associated with lithium-ion batteries.

“The study is also a nice contribution to the larger area of research on mechanically robust electrodes for electrochemical energy-storage systems,” says Vadym Mochalin, a nanomaterial expert at Drexel University in Philadelphia, who was not involved in the research. “[This] will likely inspire similar designs for lithium-ion batteries, micro-supercapacitors on chip, sensors, and other devices.”

The research is described in Nano Letters.