A material that is capable of the “reverse diffraction” of light and that is inspired by butterfly wings has been made by researchers in the US. The structure combines features of the butterfly’s reverse-diffraction grating with a normal diffraction grating, giving it additional properties that are not present in the natural structure. The researchers believe its applications could range from solar cells and LEDs to security labelling.

Many animals have evolved elaborate colour schemes, often to attract mates or confuse predators. In 2010 Jean Pol Vigneron and colleagues at the University of Namur in Belgium, together with collaborators in Panama, discovered something curious about the iridescent spot on the wings of the male Pieralla Luna butterfly, commonly known as the forest-floor satyr. The colours are produced because the scales on the butterfly’s wing behave as diffraction gratings, albeit with a twist. In a normal diffraction grating, the light with the longest wavelengths diffracts the most; so as the viewing angle becomes more oblique, the colour changes from violet to green to red. The spot on the Pieralla Luna‘s wing, however, changes colour the other way round: it looks violet when viewed obliquely and red when viewed almost straight on.

Analysing the wing’s structure, Vigneron and colleagues found that the diffraction arises from scalloped ridge patterns on the surfaces of the wing scales: these scales curve upwards at the edges, forming diffraction gratings that are perpendicular to the wing. The function of this structure to the butterfly remains unclear, although its absence from females of the species suggests a sexual-signalling role (see “Drab butterfly reveals its hidden colours”).

Regular rows and columns

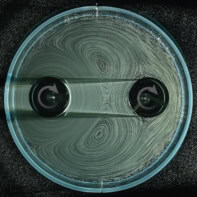

Now, researchers at Harvard University have replicated this structure using micron-scale silicon plates with scalloped edges, and have added their own twist. The scales on a wing are tens of microns apart, and are irregularly spaced, so there is no coherence between the light reflected by different scales. On their silicon-plate grating, however, the researchers arranged pillars of plates in a regular rectangular pattern, with rows separated by just 5 μm and columns by 10 μm (see image above). This periodicity allows the plates to behave collectively as a “hierarchical double-diffraction grating” – a normal diffraction grating in which each diffraction element is itself a reverse-diffraction grating.

The vertical diffraction elements (the scallops on the plates responsible for the reverse diffraction) are much closer together than the normal diffraction elements (the plates themselves), so the reverse-diffraction pattern is much more widely spread. “Because it’s a much smaller periodicity, you only see one order from it in the actual experimental results,” explains Harvard’s Grant England. The combined diffraction pattern shows multiple sets of diffraction fringes from the normal diffraction pattern, but the relative intensity of the colours in each set of fringes is modulated by the broad fringes of the reverse-diffraction pattern.

The two diffraction gratings can be manipulated independently, giving the researchers more control over the combined diffraction pattern. By moving the plates closer together or farther apart, the positions of the diffraction orders from the periodic plates are shifted, while the superimposed reverse-diffraction pattern remains unaffected. Conversely, when the researchers shear the surface, thereby bending the plates without altering their spacing, the angle of incidence of light on the reverse-diffraction gratings is altered, while the incident angle on the normal diffraction grating stays the same. Each set of fringes stays in the same position but the relative intensities of the colours in each fringe change.

Multiple copies

The researchers used industrially compatible techniques to produce the bio-inspired gratings, etching a single master before producing as many copies as needed, and team member Mathias Kolle believes that the structure could have multiple technological uses. “In the butterfly case, it’s very likely a display feature,” he says. “For signalling purposes, it would be a uniquely identifiable structure, so the obvious thing we thought about was security printing.” He suggests that the technology could be used in the authenticator labels of banknotes and credit cards. Beyond that, he sees possible applications for light management in LEDs or photovoltaic cells.

Roy Sambles, a metamaterials scientist at the University of Exeter in the UK, says that “Maxwell’s equations are well known; the equations of diffraction are well known – there is nothing new in the diffractive optics.” He is more impressed, however, by the engineering. “You’ve got a multi-stacked diffractive structure in the vertical direction and then you’ve got diffraction gratings in both directions in the horizontal plane; so in some senses it’s a triple diffractive structure – which is really quite neat and quite a clever piece of technology,” he says.

The research is published in Proceedings of the National Academy of Sciences.