Researchers at the Massachusetts Institute of Technology (MIT) have measured how far heat-carrying lattice vibrations – or phonons – travel in a material using a table-top optical spectroscopy technique. Phonons are normally studied using neutron scattering and other methods that require access to major facilities, so the new method makes it easier to characterize the thermal properties of materials. Indeed, the technique could help in the design of computer chips that run cooler and lead to better thermoelectric materials that convert heat into electricity.

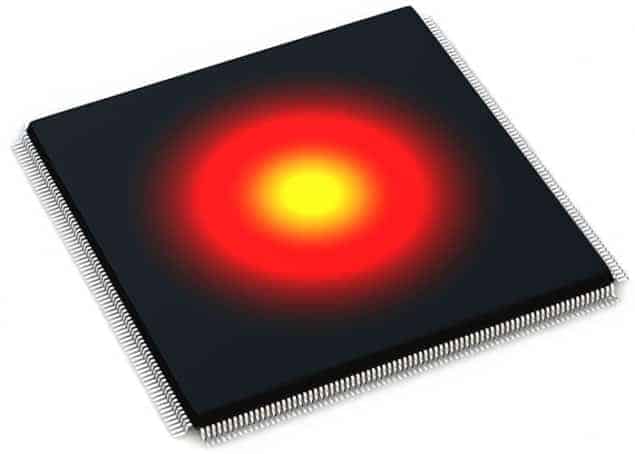

The diffusion of heat in relatively large objects is well described by Fourier’s law, which relates the rate of heat transfer to the difference in temperature between hot and cold regions. Heat energy is carried through materials by phonons, and Fourier’s law applies when the distance a phonon can travel before scattering – its mean free path – is much smaller than the object. However, this does not apply to many of the nanostructures in today’s computer chips, making it difficult to understand how heat flows out of these objects without having detailed knowledge of how the phonons behave.

Large facilities

To further complicate matters, different phonon modes in the same material can have different mean free paths, which must be taken into consideration when working out heat transfer at the nanoscale. However, measuring the mean free paths of phonons in materials is an onerous task, as lead researcher Gang Chen explains. “Extracting the mean free path of phonons normally relies on techniques such as inelastic neutron scattering on single crystals, which requires large facilities that are not always readily available or accessible,” he says. “Our work shows that we can do it on an optical table in the lab.”

The researchers studied heat dissipation from tiny metallic dots – the smallest measuring around 30 nm across – patterned on a substrate such as silicon or silicon–germanium crystals. They began by heating their samples using an intense, ultrashort laser pulse. The dots are heated by absorbing the energy from the laser and the heat is conducted to the underlying material. A second and much weaker laser pulse is then fired at the dot to measure its temperature using an established technique called time-domain thermoreflectance.

“Since some of the phonons in our sample have longer mean free paths than the size of the dots, we cannot describe heat conduction by the ‘classic’ Fourier heat-diffusion theory,” Chen explains. “Instead, heat is conducted in a regime that we call ‘quasi-ballistic’. By varying the dot size, we sample different phonons with different mean free paths. And since laser beams may excite both electrons and holes in the semiconductors we studied (something that complicates the signal), we design the structures in such a way as to avoid this problem.”

Hotter than predicted

He adds that the technique is a new way to extract phonon mean free paths in solids. “Our work also reveals that when the heat source is smaller than the distance travelled by phonons, the Fourier law underestimates how hot the heat source becomes. This has implications for modelling the thermal properties of materials and designing microelectronics devices, which are in fact currently modelled as obeying the Fourier law,” he says.

The results imply that in the drain region of semiconductor devices such as metal-oxide-semiconductor field-effect transistors (MOSFETs), the temperature rise may be higher than predictions based on the bulk thermal conductivity. Heat is typically dissipated in this region, which is around tens of nanometres thick.

Many applications

Controlling the thermal properties of such materials is important for many applications, including thermoelectrics, for thermal insulation, and for dissipating waste heat in integrated circuits. However, doing this is more difficult than it might seem, since thermal transport in solids generally involves heat carriers travelling over varying distances and it is not easy to determine how these carriers distribute themselves in a sample.

The team, which includes Mildred Dresselhaus of MIT, Lingping Zeng, who is in Chen’s group at MIT, Yongjie Hu of the University of California, Los Angeles, and Austin Minnich of the California Institute of Technology, says that it is now busy further improving and simplifying its technique so that it can be used to characterize the thermal properties of a host of other materials.

The research is described in Nature Nanotechnology.

- This article first appeared on nanotechweb.org