A new model of the slipperiness of ice suggests that a layer of disordered ice forms underneath a sliding object. The model was developed by Bo Persson of Forschungszentrum Jülich in Germany, and it could ultimately find practical application in helping to develop better skis, or improve traction in winter footwear or tyres.

Ice is, counterintuitively, not inherently slippery. Instead, it becomes so through the formation of a thin layer of meltwater on its surface. This liquid water can be created either by frictional heat or through a phase transition called premelting, which can occur at temperatures below the freezing point of water.

While premelting of ice surfaces has been studied extensively, the extent to which it plays a role in ice friction has long been unclear, explains Persson. Part of the challenge of investigating ice friction is that the interface between the ice and the object sliding across it is not easily accessible to molecular-level analytical techniques.

Shear stress

The core of Persson’s new study links a theoretical description of ice friction to existing experimental data. The outcome is a shear-stress law that can explain ice friction in terms of the sliding speed and temperature across a wide range of values. Sheer stress is the internal pressure in a material that occurs when that material is subjected to an external force along its surface. “To explain the measured data,” Persson says, “one must assume that the frictional shear stress in the area of real contact (which is very small compared with the apparent contact area because of surface roughness) decreases continuously towards zero as the temperature of the ice in the contact region approaches the bulk melting temperature.”

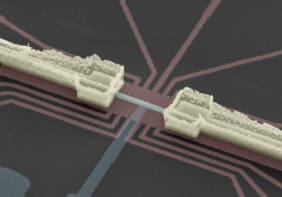

As the melting of ice is an abrupt phase transition, this decrease in friction with increasing sliding speed occurs more slowly than might be anticipated. Persson proposes two possible explanations. The first is that uneven frictional heating temporarily results in a nanometre-thick layer in which the ice is in a mixed state of adjacent, ice-like and water-like domains. Alternatively, a homogenous, heat-softened layer of disordered ice may form – and have a shear stress that decreases as the temperature increases up to the bulk melting temperature.

The latter, Persson says, is more likely, both given that heat softening is known to take place on the surface of ice, and that “the mathematical form of the frictional shear stress is consistent with what one may expect for premelting”.

Softening while sliding

Peter Sammonds and Ben Lishman of University College London and Dan Hatton of Plymouth University in the UK have collaborated on a previous study of ice friction, and they say that Persson “really adds something in pointing out that that lubrication is not the only factor, and that ice softening also plays a big part in the velocity-weakening friction regime”. They also point out that ice softening during sliding could possibly lead to larger contact areas between ice and slider when the slider stops moving. This in turn would affect the static friction between the ice and the slider, and lead to a memory effect in ice friction.

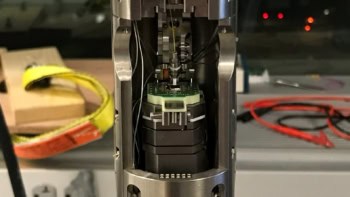

With this initial study complete, Persson is now moving to further refine his theory. To this end, he and his colleagues have constructed a sliding-friction instrument that can be cooled to –40 °C. This will allow them to incorporate a detailed measure of the impact on ice topography into the theoretical model.

At the same time, Persson is also conducting related work on rubber-on-ice friction, an area of study with particular relevance to the fabrication of winter tyres and the soles of shoes. In these cases, a different frictional process is likely to be dominant, Persson explains, one in which the surface roughness of the ice causes the rubber to deform, resulting in the dissipation of energy.

The research is described in The Journal of Chemical Physics.