Flash Physics is our daily pick of the latest need-to-know developments from the global physics community selected by Physics World‘s team of editors and reporters

Tiny glass castles and pretzels made by 3D printing

Researchers in Germany have created tiny glass pretzels and castles using 3D printing. Although glass plays a vital role in our day-to-day lives, it is notoriously difficult to shape. Making large glass objects requires high temperatures for melting and casting, and microscopic features involve the use of hazardous chemicals. As a result, modern manufacturing methods such as 3D printing have not been used for glass – but now a team at the Karlsruhe Institute of Technology (KIT) in Germany have found a solution that uses a readily available printing setup. By mixing a curable monomer with silicon dioxide powder, Bastian Rapp and colleagues created a nanocomposite mixture dubbed “liquid glass”, which becomes solid under ultraviolet (UV) light. The team used the liquid glass as “ink” in a stereolithography 3D printer – a standard setup that uses laser light (in this case UV light) to solidify the printed structure. The resulting 3D composite was then heated to 1300 °C to convert it into fused silica glass. Using this method, Rapp and team were able to create smooth and transparent structures with micron-sized features, including a microfluidic chip, a honeycomb structure, a castle and a pretzel. Coloured glass could also be created by simply incorporating metal salts into the liquid glass ink. As glass has a number of useful properties – including optical transparency, thermal and electrical insulation and chemical resistance – it is an important material in industry and scientific research. Therefore, being able to easily create macro- and micro-structures through modern techniques opens up possible new manufacturing routes and materials. The method is presented in Nature.

Laser fusion produces more neutrons

Physicists in China have unveiled a new way of creating neutrons by firing a powerful laser at a hydrogen target. Capable of producing 100 times more neutrons than current laser techniques, the method has been developed by Jie Liu of the Institute of Applied Physics and Computational Mathematics in Beijing and colleagues. It involves using a laser pulse to heat and compress a capsule (or hohlraum) containing deuterium. The intense heat causes pairs of deuterium nuclei to fuse in a process that gives off neutrons. Called inertial confinement fusion, the technique has already been investigated as a potential source of neutrons. However, the inherent instability of the process has meant that previous schemes were inefficient or unreliable sources of the particles. Liu and colleagues improved the stability of the process by using a new scheme called spherically convergent plasma fusion. This uses a spherical hohlraum with a thin gold wall that is coated on the inside with polystyrene containing deuterium. The laser pulse drives the deuterium to the centre of the hohlraum, where fusion occurs. Using a 6.3 kJ laser pulse with a duration of about 2 ns, the team was able to produce around one billion neutrons per pulse – about 100 times more than previous methods could achieve. Writing in Physical Review Letters, Liu and colleagues point out that using a target containing deuterium and tritium could boost the neutron output by an additional factor of 1000 – and even more if a higher-power laser is used.

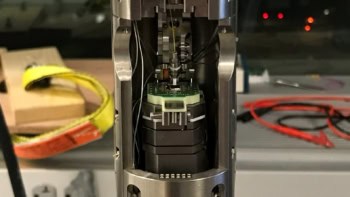

Cash boost for UK’s MAST tokamak

The Mega Amp Spherical Tokamak (MAST) at the Culham Centre for Fusion Energy (CCFE) in Oxfordshire has received £21m for a series of upgrades to study the best way to extract waste fuel from the plasma it contains. MAST has a spherical plasma, shaped much like a cored-out apple, whereas a conventional tokamak such as ITER has a doughnut-shaped plasma. A spherical tokamak allows for a much more compact – and cheaper – device and it is hoped that this kind of tokamak could one day be used as a potential fusion reactor. MAST is nearing the end of a £45m upgrade that will see the tokamak given a new “divertor”, which extracts the waste fuel from fusion. Called “Super-X”, it is hoped that the new divertor could even be used in a future demonstration fusion plant – dubbed DEMO. The new cash, from the European Fusion Research Consortium and the UK’s Engineering and Physical Sciences Research Council, will be used to increase the tokamak’s plasma heating power as well as upgrade the plasma control systems and add extra plasma diagnosis equipment. These improvements are set to be introduced over the next five years.

- You can find all our daily Flash Physics posts in the website’s news section, as well as on Twitter and Facebook using #FlashPhysics. Tune in to physicsworld.com later today to read today’s extensive news story on the origin of binary black holes.