Uranium has been extracted from seawater using electrochemical methods. A team at Stanford University in California has removed the radioactive material from seawater by using a polymer–carbon electrode and applying a pulsed electric field.

Uranium is a key component of nuclear fuel. On land, there are about 7.6 million tonnes of identified uranium deposits around the world. This ore is mined, processed and used for nuclear energy. In contrast, there is 4.5 billion tonnes of the heavy metal in seawater as a result of the natural weathering of undersea deposits. If uranium could be extracted from seawater, it could be used to fuel nuclear power stations for hundreds of years. As well as taking advantage of an untapped energy resource, seawater extraction would also avoid the negative environmental impacts of mining processes.

Tiny concentrations

Scientists are therefore working on methods to remove and recover uranium from the sea. However, the oceans are vast, and the concentration of uranium is only 3 μg/l, making the development of practical extraction techniques a significant challenge. “Concentrations are tiny, on the order of a single grain of salt dissolved in a litre of water,” says team member Yi Cui. Furthermore, the high salt content of seawater limits traditional extraction methods.

In water, uranium typically exists as a positively charged uranium oxide, or uranyl, ion (UO2+2). Most methods for extraction involve an adsorbent material where the uranyl ion attaches to the surface but does not chemically react with it. The current leading materials are amidoxime polymers. The performance of adsorbents is, however, limited by their surface area. As there are only a certain number of adsorption sites, and the concentration of uranium is extremely low compared with other positive ions like sodium and calcium, the uranium-adsorbent interaction is slow and sites are quickly taken up by other ions. Furthermore, the adsorbed ions still carry a positive charge and therefore repel other uranyl ions away from the material.

Electrochemical answer

Cui and his team turned to electrochemistry and deposition for a solution to this problem. In a basic electrochemical cell, there is an electrolyte solution and two submerged electrodes connected to a power supply. By providing the electrodes with opposite charges, an electrical current is driven through the liquid, forcing positive ions to the negative electrode, and electrons and negative ions to the positive electrode. At the negative electrode, called the anode, the positive ions are reduced, meaning they gain electrons. For most metallic ions, this causes the precipitation of the solid metal and is often deposited on the electrode surface.

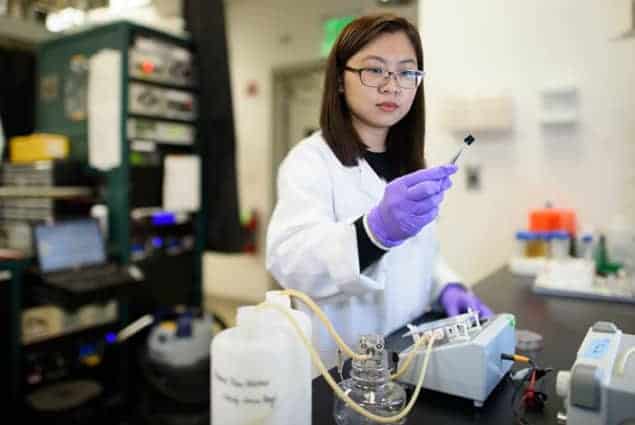

In their electrochemical cell, the team used an anode made of carbon coated with amidoxime polymer, and an inert partner electrode. The electrolyte was seawater, which for some tests contained added uranium. By applying a short pulse of current, the positive uranyl, calcium and sodium ions were drawn to the carbon–polymer electrode. The amidoxime film encouraged the uranyl ions to be preferentially adsorbed over the other ions. The adsorbed uranyl ions were reduced to solid, charge-neutral uranium oxide (UO2) and once the current was switched off, the unwanted ions returned to the bulk of the electrolyte. By repeating the pulsed process, the researchers were able to build up the deposited uranium oxide on the electrode surface, no matter what the initial concentration of the solution was.

Removal and recovery

In tests comparing the new method to plain adsorptive amidoxime, the electrochemical cell significantly outperformed the more traditional material. Within the time it took the amidoxime surface to become saturated, the carbon–polymer electrode had extracted nine times the amount of uranium. Furthermore, the team demonstrated that 96.6% of the metal could be recovered from the surface by applying a reverse current and an acidic electrolyte. For an adsorption material, only 76.0% can be recovered with acid elution.

Despite the researchers’ success, there is a long way to go before large-scale application. To be commercially viable, the benefits of the extracted uranium must outweigh the cost and power demands of the process. Furthermore, the process needs to be streamlined to treat large quantities of water. “We have a lot of work to do still but these are big steps toward practicality,” Cui concludes.

The extraction method is described in Nature Energy.