An octopus-inspired adhesive surface that works in wet and dry conditions has been created by researchers in South Korea. They believe their suction cups could find a range of uses including the manufacture of silicon chips and wound healing. The research also provides a better understanding of why the suction cups of the common octopus are so good at grabbing hold of surfaces.

The limbs of octopuses are covered with suction cups, which the animals use to pull themselves along and catch prey. The suction cups of the common octopus are particularly interesting, containing a central bump whose function had previously been unknown.

Adhesives are required in all sorts of different applications, from keeping packages shut to closing wounds after major surgery. However, glue can lose its stickiness after a while, and can leave chemical contamination on surfaces. Imaginative solutions using charged polymers, nanoparticle solutions and systems inspired by various living creatures have been tested, but they can be difficult to manufacture. As a result, creating contamination-free, easily manufactured adhesives that stick repeatedly to wet and dry surfaces of variable geometries remains a challenge.

Polymer moulds

In the new research, Changhyun Pang and colleagues at Sungkyunkwang University in South Korea fabricated polymer surfaces covered with thousands of miniature replicas of the octopus suction cups – complete with central bumps. The team made several versions of the surfaces with suction cups of different diameters in the 15–500 μm range. The structures are easily produced by pouring a polymer into a mould.

The researchers tested their film’s adhesiveness to a silicon wafer – and compared the results with the adhesiveness of films covered with similarly sized cylindrical holes, solid cylindrical pillars and hollow cylindrical pillars. They found the octopus-like structures were significantly more effective than the others in damp conditions or when fully submerged in water. Indeed, strong adhesion was even achieved in silicone oil, which is used as a lubricant.

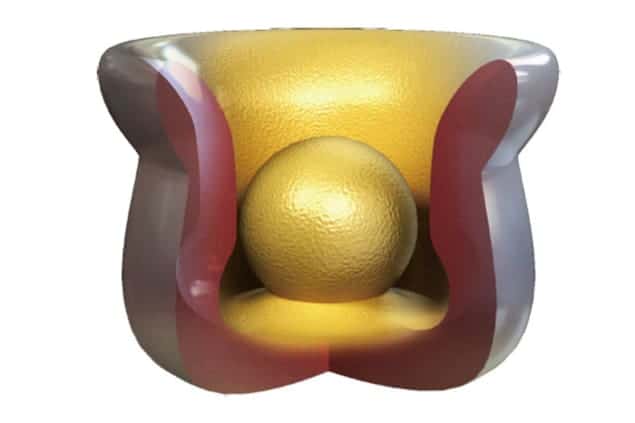

When one of the suction cups is gently pressed into a surface in the presence of liquid, it contracts, pushing some of the fluid out. When the cup expands again, the pressure inside is lower than outside, creating suction. If more force is applied, the octopus-inspired dome-like protuberance in the middle of the suction cup flattens, expanding sideways until it touches the edges of the cup. This divides the cup into upper and lower chambers. Capillary forces draw the liquid into the upper chamber. When the pressure is released, cohesive forces between the liquid molecules in the upper chamber keep the protuberance flattened, holding the upper chamber shut and creating extremely low pressure in the lower chamber.

Fluorescent water

This two-stage suction process could explain why the octopus-inspired surface attaches to the wafer much more strongly if the two surfaces are pressed together harder, whereas surfaces covered with the other structures often show little or no increase in suction. The researchers confirmed their model by using confocal microscopy to study the movement of fluorescently labelled water within the suction cups.

The ability to hold a silicon wafer could be useful in the semiconductor industry, where wafers have to be transported precisely and repeatedly in both dry and wet conditions – an expensive process that can also damage the wafers. Pang and colleagues have shown that their adhesive surface can do the job in a repetitive industrial setting because it shows no loss of suction after more than 10,000 cycles of attachment and detachment. They also showed that saline-loaded patches can stick to mouse skin and assist wound healing, although less effectively than the standard current medical dressing: “Our group is currently investigating stem-cell- and drug-loading approaches to improve these patches’ practical utility,” says Pang.

Rough surfaces

Solid and structural mechanics expert Nicola Pugno of the University of Trento in Italy believes that the work is significant. He points out that while the adhesiveness of a large conventional suction cup is comparable or slightly higher that the new surface, large suction cups cannot attach to very small or rough surfaces.

He also says that producing a film embedded with microscopic conventional suction cups would be very difficult: “A suction cup seems to be simple but, as a geometry, it’s quite complex: it’s tapered, for example.” “Perhaps the most interesting aspect is that they were able to produce in large area these microscopic, strange suction cups with the peculiar geometry of the octopus suction cups. When you understand all the physics and optimise everything, perhaps you can achieve an order of magnitude increase in adhesion strength.”

The invention is described in Nature.