A new technique for fine-tuning frictional forces at the interfaces between different materials has been developed by researchers in France. Julien Scheibert and colleagues at the University of Lyon used simple and easily-adjustable metasurfaces to create specific coefficients of friction at the interface between glass and elastomer samples.

From touchscreens to robotic hands, frictional contacts are a key component of many modern devices. To optimize their performance, designers need to establish tight control over the frictional forces at material interfaces. However, despite centuries of careful investigation, we still do not have a reliable method for predicting the coefficient of friction across any given interface.

The main difficulty in understanding friction is the sheer diversity of textures found on surfaces. The size of surface features can span several orders of magnitude: from atomic to millimetre scales. Since all of these features can influence the friction between two surfaces, it is often incredibly difficult calculate friction coefficients from first principles.

Currently, there are two main techniques for optimizing the friction between surfaces. One method is to simply select a pair of materials that experience the correct amount of friction. However, it is often the case that these materials do not have the other properties – thermal, electrical etc. – that are required for a specific application.

Poor understanding

“The second technique is to create artificial microtextures on the surfaces,” Scheibert explains. “But because the relationship between texture and friction remains poorly understood, suitable textures are usually only identified after long and costly experimental campaigns.”

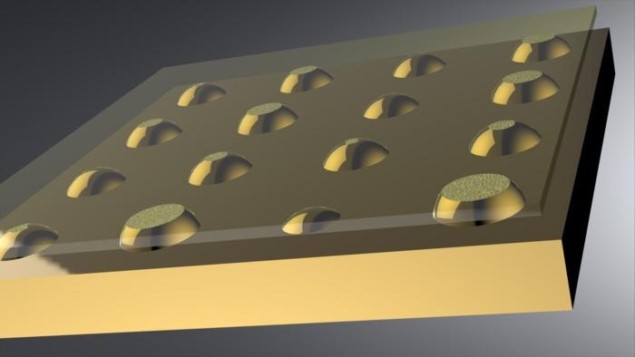

In their study, Scheibert’s team improved on the microtextural approach by using very simple metasurfaces that comprise square arrays of spherical caps. Each cap can be given a specific height with respect to the other caps (see figure).

“In these conditions, the [frictional] response of the interface can be modelled accurately, and the list of heights that offers the targeted friction behaviour can be determined before actually manufacturing the surfaces,” Scheibert explains. In this way, the team could engineer different textures to achieve the desired level of interfacial friction on the first try.

The researchers tested their approach by preparing metasurfaces on centimetre-sized samples of a rubber-like elastomer. Each surface featured a lattice of 64 spherical caps made of elastomer. The height at which each cap protrudes from the surface is set individually, allowing the team to create a range of different metasurfaces.

Friction is measured by placing a flat piece of glass on top of the metasurface and pushing down while dragging the glass along the metasurface. By adjusting the structure of the metasurfaces in a systematic way, specific coefficients of friction could be created at the interface.

Two different friction coefficients

The approach worked without any need for first-principles calculations of frictional forces, and without changing any properties of the materials themselves. “Even more, we have prepared contacts featuring two different friction coefficients, which depend on the level of compression applied to the interface – a behaviour that is very rare in nature,” Scheibert adds.

Friction does the heavy lifting in ropes and yarns

With this quick and affordable approach, Scheibert’s team were able to reproduce a variety of known friction laws in their experiments: including linear laws, where the coefficient friction stays constant as shear forces increase across the interface; and more complex nonlinear laws, where this coefficient varies with shear force.

As they improve their technique further, the researchers envisage a wide array of applications for their adjustable metasurface approach. “Creating contact interfaces matching a specified friction behaviour is the Holy Grail in tribology,” says Scheibert.

“Our design strategy provides new tools for preparing such frictional interfaces. This could potentially open up opportunities in various challenging fields, from sports to soft robotics. If further equipped with sensors and actuators, our metainterfaces even hold the promise of smart contact interfaces with real-time friction tuning.”

The research is described in Science.