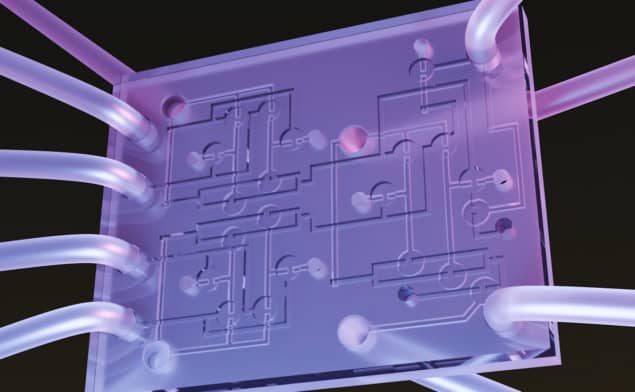

A device containing a pneumatic logic circuit made from 21 microfluidic valves could be used as a new type of air-powered computer that does not require any electronic components. The device could help make a wide range of important air-powered systems safer and less expensive, according to its developers at the University of California at Riverside.

Electronic computers rely on transistors to control the flow of electricity. But in the new air-powered computer, the researchers use tiny valves instead of transistors to control the flow of air rather than electricity. “These air-powered computers are an example of microfluidics, a decades-old field that studies the flow of fluids (usually liquids but sometimes gases) through tiny networks of channels and valves,” explains team leader William Grover, a bioengineer at UC Riverside.

By combining multiple microfluidic valves, the researchers were able to make air-powered versions of standard logic gates. For example, they combined two valves in a row to make a Boolean AND gate. This gate works because air will flow through the two valves only if both are open. Similarly, two valves connected in parallel make a Boolean OR gate. Here, air will flow if either one or the other of the valves is open.

Complex logic circuits

Combining an increasing number of microfluidic valves enables the creation of complex air-powered logic circuits. In the new study, detailed in Device, Grover and colleagues made a device that uses 21 microfluidic valves to perform a parity bit calculation – an important calculation employed by many electronic computers to detect errors and other problems.

The novel air-powered computer detects differences in air pressure flowing through the valves to count the number of bits. If there is an error, it outputs an error signal by blowing a whistle. As a proof-of-concept, the researchers used their device to detect anomalies in an intermittent pneumatic compression (IPC) device – a leg sleeve that fills with air and regularly squeezes a patient’s legs to increase blood flow, with the aim of preventing blood clots that could lead to strokes. Normally, these machines are monitored using electronic equipment.

“IPC devices can save lives, but they aren’t as widely employed as they could be,” says Grover. “In part, this is because they’re so expensive. We wanted to see if we could reduce their cost by replacing some of their electronic hardware with pneumatic logic.”

Air’s viscosity is important

Air-powered computers behave very similarly, but not quite identically to electronic computers, Grover adds. “For example, we can often take an existing electronic circuit and make an air-powered version of it and it’ll work just fine, but at other times the air-powered device will behave completely differently and we have to tweak the design to make it function.”

The variations between the two types of computers come down to one important physical difference between electricity and air, he explains: electricity does not have viscosity, but air does. “There are also lots of little design details that are of little consequence in electronic circuits but which become important in pneumatic circuits because of air’s viscosity. This makes our job a bit harder, but it also means we can do things with pneumatic logic that aren’t possible – or are much harder to do – with electronic logic.”

In this work, the researchers focused on biomedical applications for their air-powered computer, but they say that this is just the “tip of the iceberg” for this technology. Air-powered systems are ubiquitous, from the brakes on a train, to assembly-line robots and medical ventilators, to name but three. “By using air-powered computers to operate and monitor these systems, we could make these important systems more affordable, more reliable and safer,” says Grover.

“I have been developing air-powered logic for around 20 years now, and we’re always looking for new applications,” he tells Physics World. “What is more, there are areas in which they have advantages over conventional electronic computers.”

One specific application of interest is moving grain inside silos, he says. These enormous structures hold grain and other agricultural products and people often have to climb inside to spread out the grain – an extremely dangerous task because they can become trapped and suffocate.

Kirigami cubes make a novel mechanical computer

“Robots could take the place of humans here, but conventional electronic robots could generate electronic sparks that could create flammable dust inside the silo,” Grover explains. “An air-powered robot, on the other hand, would work inside the silo without this risk. We are thus working on an air-powered ‘brain’ for such a robot to keep people out of harm’s way.”

Air-powered computers aren’t a new idea, he adds. Decades ago, there was a multitude of devices being designed that ran on water or air to perform calculations. Air-powered computers fell out of favour, however, when transistors and integrated circuits made electronic computers feasible. “We’ve therefore largely forgotten the history of computers that ran on things other than electricity. Hopefully, our new work will encourage more researchers to explore new applications for these devices.”