A new type of composite material is 10 times more efficient at extracting gold from electronic waste than previous adsorbents. Developed by researchers in Singapore, the UK and China, the environmentally-friendly composite is made from graphene oxide and a natural biopolymer called chitosan, and it filters the gold without an external power source, making it an attractive alternative to older, more energy-intensive techniques.

Getting better at extracting gold from electronic waste, or e-waste, is desirable for two reasons. As well as reducing the volume of e-waste, it would lessen our reliance on mining and refining new gold, which involves environmentally hazardous materials such as activated carbon and cyanides. Electronic waste management is a relatively new field, however, and existing techniques like electrolysis are time-consuming and require a lot of energy.

A more efficient and suitable recovery process

Led by Kostya Novoselov and Daria Andreeva of the Institute for Functional Intelligent Materials at the National University of Singapore, the researchers chose graphene and chitosan because both have desirable characteristics for gold extraction. Graphene boasts a high surface area, making it ideal for adsorbing ions, they explain, while chitosan acts as a natural reducing agent, catalytically converting ionic gold into its solid metallic form.

While neither material is efficient enough to compete with conventional methods such as activated carbon on its own, Andreeva says they work well together. “By combining both of them, we enhance both the adsorption capacity of graphene and the catalytic reduction ability of chitosan,” she explains. “The result is a more efficient and suitable gold recovery process.”

High extraction efficiency

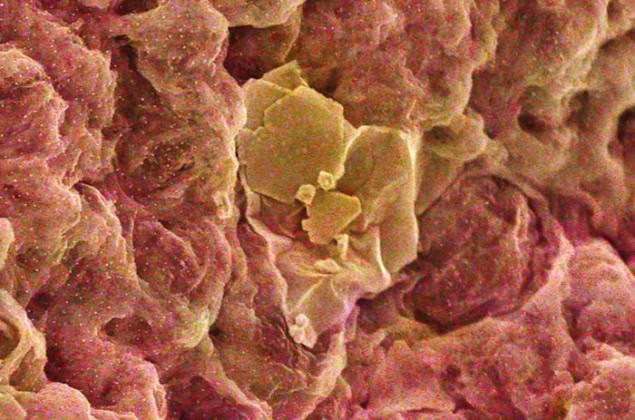

The researchers made the composite by getting one-dimensional chitosan macromolecules to self-assemble on two-dimensional flakes of graphene oxide. This assembly process triggers the formation of sites that bind gold ions. The enhanced extracting ability of the composite comes from the fact that the ion binding is cooperative, meaning that an ion binding at one site allows other ions to bind, too. The team had previously used similar methods in studies that focused on structures such as novel membranes with artificial ionic channels, anticorrosion coatings, sensors and actuators, switchable water valves and bioelectrochemical systems.

Once the gold ions are adsorbed onto the graphene surface, the chitosan catalyses the reduction of these ions, converting them from their ionic state into solid metallic gold, Andreeva explains. “This combined action of adsorption and reduction makes the process both highly efficient and environmentally friendly, as it avoids the use of harsh chemicals typically employed in gold recovery from electronic waste,” she says.

The researchers tested the material on a real waste mixture provided by SG Recycle Group SG3R, Pte, Ltd. Using this mixture, which contained gold in a residual concentration of just 3 ppm, they showed that the composite can extract nearly 17g/g of Au3+ ions and just over 6 g/g of Au+ from a solution – values that are 10 times larger than existing gold adsorbents. The material also has an extraction efficiency of above 99.5 percent by weight (wt%), breaking the current of limit of 75 wt%. To top it off, the ion extraction process is ultrafast, taking around just 10 minutes compared to days for other graphene-based adsorbents.

No applied voltage required

The researchers, who report their work in PNAS, say that the multidimensional architecture of the composite’s structure means that no applied voltage is required to adsorb and reduce gold ions. Instead, the technique relies solely on the chemisorption kinetics of gold ions on the heterogenous graphene oxide/chitosan nanoconfinement channels and the chemical reduction at multiple binding sites. The new process therefore offers a cleaner, more efficient and environmentally-friendly method for recovering gold from electronic waste, they add.

Flash heating technique extracts valuable metals from battery waste quickly and cheaply

While the present work focused on gold, the team say the technique could be adapted to recover other valuable metals such as silver, platinum or palladium from electronic waste or even mining residues. And that is not all: as well as e-waste, the technology might be applied to a wider range of environmental cleaning efforts, such as filtering out heavy metals from polluted water sources or industrial effluents. “It thus provides a solution for reducing metal contamination in ecosystems,” Andreeva says.

Other possible applications areas, she adds, include sustainable decarbonization and hydrogen production, low-dimensional building blocks for embedding artificial neural networks in hardware for neuromorphic computing and biomedical applications.

The Singapore researchers are now studying how to regenerate and reuse the composite material itself, to further reduce waste and improve the process’s sustainability. “Our ongoing research is focusing on optimizing the material’s properties, bringing us closer to a scalable, eco-friendly solution for e-waste management and beyond,” Andreeva says.