Researchers and engineers who require vacuum environments for their projects can simplify their design process and achieve better results by collaborating with the technology experts at Agilent

Whether creating a contaminant-free environment for depositing material or minimizing unwanted collisions in spectrometers and accelerators, vacuum environments are a crucial element of many scientific endeavours. Creating and maintaining very low pressures requires a holistic approach to system design that includes material selection, preparation, and optimization of the vacuum chamber and connection volumes. Measurement strategies also need to be considered across the full range of vacuum to ensure consistent performance and deliver the expected outcomes from the experiment or process.

Developing a vacuum system that achieves the optimal low-pressure conditions for each application, while also controlling the cost and footprint of the system, is a complex balancing act that benefits from specialized expertise in vacuum science and engineering. A committed technology partner with extensive experience of working with customers to design vacuum systems, including those for physics research, can help to define the optimum technologies that will produce the best solution for each application.

Over many years, the technology experts at Agilent have assisted countless customers with configuring and enhancing their vacuum processes. “Our best successes come from collaborations where we take the time to understand the customer’s needs, offer them guidance, and work together to create innovative solutions,” comments John Screech, senior applications engineer at Agilent. “We strive to be a trusted partner rather than just a commercial vendor, ensuring our customers not only have the right tools for their needs, but also the information they need to achieve their goals.”

In his role Screech works with customers from the initial design phase all the way through to installation and troubleshooting. “Many of our customers know they need vacuum, but they don’t have the time or resources to really understand the individual components and how they should be put together,” he says. “We are available to provide full support to help customers create a complete system that performs reliably and meets the requirements of their application.”

In one instance, Screech was able to assist a customer who had been using an older technology to create an ultrahigh vacuum environment. “Their system was able to produce the vacuum they needed, but it was unreliable and difficult to operate,” he remembers. By identifying the problem and supporting the migration to a modern, simpler technology, Screech helped his customer to achieve the required vacuum conditions improve uptime and increase throughput.

Agilent collaborates with various systems integrators to create custom vacuum solutions for scientific instruments and processes. Such customized designs must be compact enough to be integrated within the system, while also delivering the required vacuum performance at a cost-effective price point. “Customers trust us to find a practical and reliable solution, and realize that we will be a committed partner over the long term,” says Screech.

Expert partnership yields success

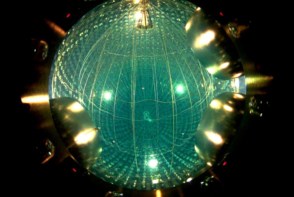

The company also partners with leading space agencies and particle physics laboratories to create customized vacuum solutions for the most demanding applications. For many years, Agilent has supplied high-performance vacuum pumps to CERN, which created the world’s largest vacuum system to prevent unwanted collisions between accelerated particles and residual gas molecules in the Large Hadron Collider.

When engineering a vacuum solution that meets the exact specifications of the facility, one key consideration is the physical footprint of the equipment. Another is ensuring that the required pumping performance is achieved without introducing any unwanted effects – such as stray magnetic fields – into the highly controlled environment. Agilent vacuum experts have the experience and knowledge to engineer innovative solutions that meet such a complex set of criteria. “These large organizations already have highly skilled vacuum engineers who understand the unique parameters of their system, but even they can benefit from our expertise to transform their requirements into a workable solution,” says Screech.

Agilent also shares its knowledge and experience through various educational opportunities in vacuum technologies, including online webinars and dedicated training courses. The practical aspects of vacuum can be challenging to learn online, so in-person classes emphasize a hands-on approach that allows participants to assemble and characterize rough- and high-vacuum systems. “In our live sessions everyone has the opportunity to bolt a system together, test which configuration will pump down faster, and gain insights into leak detection,” says Screech. “We have students from industry and academia in the classes, and they are always able to share tips and techniques with one another.” Additionally, the company maintains a vacuum community as an online resource, where questions can be posed to experts, and collaboration among users is encouraged.

Agilent recognizes that vacuum is an enabler for scientific research and that creating the ideal vacuum system can be challenging. “Customers can trust Agilent as a technology partner,” says Screech. “We can share our experience and help them create the optimal vacuum system for their needs.”

- A new webinar from Agilent, Vacuum for Physics Research, can now be viewed on demand via physicsworld.com. Further resources are available through the Agilent vacuum webinar library, or contact vacuum_training@agilent.com for more information about education and training opportunities.

- You can learn more about vacuum and leak detection technologies from Agilent through the company’s website. Alternatively, visit the partnership webpage to chat with an expert, find training, and explore the benefits of partnering with Agilent.