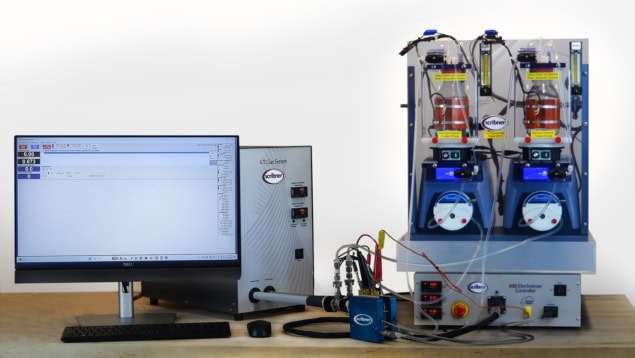

Scribner’s 670 Electrolysis Workstation is used to develop systems that convert electrical energy into fuels and chemical feedstocks

The electrochemical reduction of carbon dioxide is used to produce a range of chemical and energy feedstocks including syngas (hydrogen and carbon monoxide), formic acid, methane and ethylene. As well as being an important industrial process, the large-scale reduction of carbon dioxide by electrolysis offers a practical way to capture and utilize carbon dioxide.

As a result, developing new and improved electrochemical processes for carbon-dioxide reduction is an important R&D activity. This work involves identifying which catalyst and electrolyte materials are optimal for efficient production. And when a promising electrochemical system is identified in the lab, the work is not over because the design must be then scaled up to create an efficient and practical industrial process.

Such R&D activities must overcome several challenges in operating and characterizing potential electrochemical systems. These include maintaining the correct humidification of carbon-dioxide gas during the electrolysis process and minimizing the production of carbonates – which can clog membranes and disrupt electrolysis.

While these challenges can be daunting, they can be overcome using the 670 Electrolysis Workstation from US-based Scribner. This is a general-purpose electrolysis system designed to test the materials used in the conversion of electrical energy to fuels and chemical feedstocks – and it is ideal for developing systems for carbon-dioxide reduction.

Turn-key and customizable

The workstation is a flexible system that is both turn-key and customizable. Liquid and gas reactants can be used on one or both of the workstation’s electrodes. Scribner has equipped the 670 Electrolysis Workstation with cells that feature gas diffusion electrodes and membranes from US-based Dioxide Materials. The company specializes in the development of technologies for converting carbon dioxide into fuels and chemicals, and it was chosen by Scribner because Dioxide Materials’ products are well documented in the scientific literature.

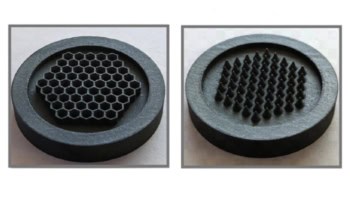

The gas diffusion electrodes are porous graphite cathodes through which carbon-dioxide gas flows between input and output ports. The gas can migrate from the graphite into a layer containing a metal catalyst. Membranes are used in electrolysis cells to ensure that only the desired ions are able to migrate across the cell, while blocking the movement of gases.

The system employs a multi-range ±20 A and 5 V potentiostat for high-accuracy operation over a wide range of reaction rates and cell sizes. The workstation is controlled by Scribner’s FlowCell™ software, which provides full control and monitoring of test cells and comes pre-loaded with a wide range of experimental protocols. This includes electrochemical impedance spectroscopy (EIS) capabilities up to 20 KHz and cyclic voltammetry protocols – both of which are used to characterize the health and performance of electrochemical systems. FlowCell™ also allows users to set up long duration experiments while providing safety monitoring with alarm settings for the purging of gases.

Humidified gas

The 670 Electrolysis Workstation features a gas handling unit that can supply humidified gas to test cells. Adding water vapour to the carbon-dioxide reactant is crucial because the water provides the protons that are needed to convert carbon dioxide to products such as methane and syngas. Humidifying gas is very difficult and getting it wrong leads to unwanted condensation in the system. The 670 Electrolysis Workstation uses temperature control to minimize condensation. The same degree of control can be difficult to achieve in homemade systems, leading to failure.

The workstation offers electrochemical cells with 5 cm2 and 25 cm2 active areas. These can be used to build carbon-dioxide reduction cells using a range of materials, catalysts and membranes – allowing the performance of these prototype cells to be thoroughly evaluated. By studying cells at these two different sizes, researchers can scale up their electrochemical systems from a preliminary experiment to something that is closer in size to an industrial system. This makes the 670 Electrolysis Workstation ideal for use across university labs, start-up companies and corporate R&D labs.

The workstation can handle, acids, bases and organic solutions. For carbon-dioxide reduction, the cell is operated with a liquid electrolyte on the positive electrode (anode) and gaseous carbon dioxide at the negative electrode (cathode). An electric potential is applied across the electrodes and the product gas comes off the cathode side.

The specific product is largely dependent on the catalyst used at the cathode. If a silver catalyst is used for example, the cell is likely to produce the syngas. If a tin catalyst is used, the product is more likely to be formic acid.

Mass spectrometry

The best way to ensure that the desired products are being made in the cell is to connect the gas output to a mass spectrometer. As a result, Scribner has joined forces with Hiden Analytical to integrate the UK-based company’s HPR-20 mass spectrometer for gas analysis. The Hiden system is specifically configured to perform continuous analysis of evolved gases and vapours from the 670 Electrolysis Workstation.

If a cell is designed to create syngas, for example, the mass spectrometer will determine exactly how much carbon monoxide is being produced and how much hydrogen is being produced. At the same time, researchers can monitor the electrochemical properties of the cell. This allows researchers to study relationships between a system’s electrical performance and the chemical species that it produces.

Monitoring gas output is crucial for optimizing electrochemical processes that minimize negative effects such as the production of carbonates, which is a significant problem when doing carbon dioxide reduction.

In electrochemical cells, carbon dioxide is dissolved in a basic solution. This results in the precipitation of carbonate salts that clog up the membranes in cells, greatly reducing performance. This is a significant problem when scaling up cell designs for industrial use because commercial cells must be very long-lived.

Pulsed-mode operation

One strategy for dealing with carbonates is to operate electrochemical cells in pulsed mode, rather than in a steady state. The off time allows the carbonates to migrate away from electrodes, which minimizes clogging. The 670 Electrolysis Workstation allows users to explore the use of short, second-scale pulses. Another option that researchers can explore is the use of pulses of fresh water to flush carbonates away from the cathode area. These and other options are available in a set of pre-programmed experiments that allow users to explore the mitigation of salt formation in their electrochemical cells.

The gaseous products of these carbonate-mitigation modes can be monitored in real time using Hiden’s mass spectrometer. This allows researchers to identify any changes in cell performance that are related to pulsed operation. Currently, electrochemical and product characteristics can be observed on time scales as short as 100 ms. This allows researchers to fine-tune how pulses are applied to minimize carbonate production and maximize the production of desired gases.

Real-time monitoring of product gases is also important when using EIS to observe the degradation of the electrochemical performance of a cell over time. This provides researchers with a fuller picture of what is happening in a cell as it ages.

The integration of Hiden’s mass spectrometer to the 670 Electrolysis Workstation is the latest innovation from Scribner. Now, the company is working on improving the time resolution of the system so that even shorter pulse durations can be studied by users. The company is also working on boosting the maximum current of the 670 to 100 A.