The Japanese art of “kirigami”, or paper cutting, has been used by scientists in the US to make electrically conductive composite sheets more elastic, increasing their strain from 4% to 370%, without significantly affecting their conductivity. The team has so far demonstrated its new technique by making stretchable plasma electrodes, but adds that its work could have a variety of applications, from reconfigurable structures to optoelectronic devices. The principles could also be used to design other composite materials that retain a specific property under mechanical strain.

Composite materials allow engineers to combine multiple materials with different properties to achieve a combination of properties not found in nature. One common tactic is to combine a strong elastic material with another that has a desired property, such as high electrical conductivity, but which is brittle. Unfortunately, microcracks can form in brittle regions, and stress then concentrates around their edges, allowing the material to fail. Using a composite with only a small proportion of brittle material can allow composites to stretch to many times their original length, but their functional properties are often drastically altered as they do so. “There is always a trade-off there,” explains Nicholas Kotov of the University of Michigan, Ann Arbor. “We want to have the cake and we want to eat it too.”

Cuts and notches

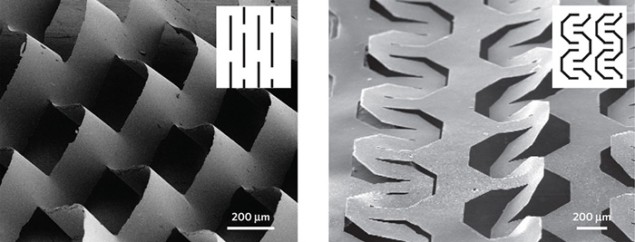

Kotov, together with Sharon Glotzer and colleagues at the University of Michigan, stressed carbon-nanotube/polymer composites designed to be electrically conductive, finding that they primarily deformed by the stretching of their internal fibres, before rupturing at around 5% strain. They then used photolithography to make a series of strategically placed cuts in the materials, according to the rules of kirigami. When they stressed the cut materials, the researchers found that they initially deformed in the same way. However, as the stress rose further, they began to absorb the extra strain energy by opening up the network of cuts, deforming out of the plane of the material and forming a “secondary elastic plateau” as the cuts gradually rotated with increasing load to align themselves with the applied stress.

As the stress increased, the cut regions were gradually pulled back to the centre, concentrating the strain onto the corners of the cuts. The materials finally ruptured when the strain on these corner regions grew too large, but not before they stretched by up to 370%. Crucially, the material’s electrical conductivity remained virtually unchanged as they stretched. The team found that it could manipulate the strength and elasticity of the materials in more detail by altering the length and spacing of the cuts.

Strained electrodes

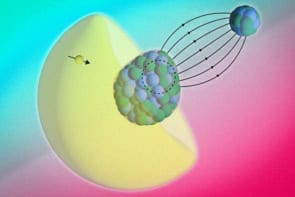

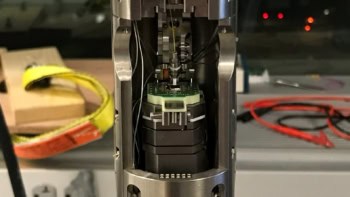

The researchers used their kirigami system to produce stretchable plasma electrodes able to generate electric fields that could ionize argon gas, and yet still withstand strains of more than 200%. This would typically destroy the plasma by either physically destroying the electrode or reducing its conductivity. “In our case it was opposite,” says Kotov, “We actually saw an increase in the intensity of the plasma spots when we strained the electrode.” This has a direct application to plasma displays, he says, which use a similar process to generate spots of light. “There are no flexible or stretchable plasma devices right now,” he says. Further applications might be found in solar cells, prosthetics or the electrodes of lithium ion batteries, which need to expand and contract repeatedly without damage or loss of conductivity during the charge/discharge cycle.

Pop-up feature

“It’s very interesting, although it’s not the only example of this kind of thing – I’ve also seen something like this in graphene,” says Christian Santangelo of the University of Massachusetts, Amherst, in the US. Santangelo is particularly interested in the “pop-up book” aspect in which, when pulled, the material buckles out of the plane. “I can imagine using this as a way to make 3D electronic devices – taking advantage of the third dimension to pack more stuff into an electronic device.” But the more immediate task, he says, is to look in detail at how the materials respond to different, more complex cuts – something that Kotov’s group is already working on.

The research is published in Nature Materials.