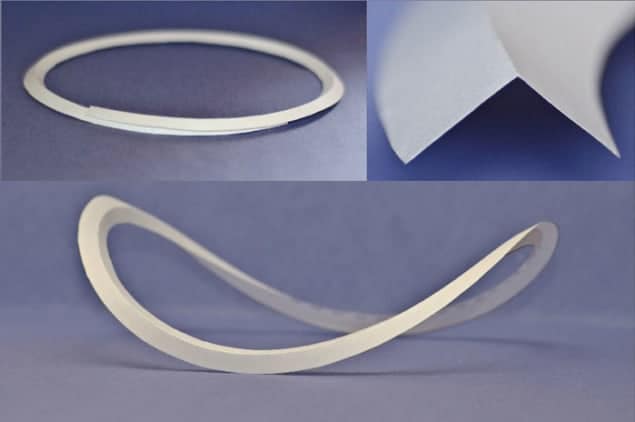

Here’s a fun exercise – take a piece of paper and use a compass to draw two concentric circles that define a ring. Then replace the pencil in the compass with a hard tip to indent a concentric crease in the paper halfway between the inner and outer edge of the ring. Cut out the ring and then fold along the crease all the way along its circumference – and if you are careful you will have created a 3D saddle such as the one in the photograph above.

This is a simple example of “curved-crease origami”, the mechanics of which have been studied in detail for the first time by physicists in the US.

Originating in Japan, origami is the art of creating 3D objects by folding paper. Origami can transform a lightweight flat material into a strong and flexible 3D object and as a result its principles have been adopted by engineers to design everything from vehicle airbags to satellite components.

Practical 3D materials

Curved creases are sometimes used in origami – a practical example being the French-fry box used in fast food restaurants. However, little is understood about the mechanics of such structures. Now, Marcelo Dias, Christian Santangelo and colleagues at the University of Massachusetts, Amherst and Harvard University are the first to develop a set of equations to describe the physics of curved-crease structures. As well as providing a better understanding of origami, the team hopes that the work will lead to practical 3D materials that are both strong and flexible.

Santangelo and colleagues focused on a ring because it is a relatively simple example of how a 2D structure can be transformed into 3D object by creating a curved crease. To gain a basic understanding of the physics, the team built a few origami saddles out of paper – from which they deduced which physical properties are key to understanding the mechanics of the curved crease.

At the heart of the transition from a 2D sheet to a 3D object are the planar stresses created in the ring when it is folded. These stresses are relieved by the sheet wrapping around itself to create a saddle-like structure. If the ring is cut, then the stresses are relieved and the saddle will collapse to a ring that will lie flat – albeit with a smaller radius (see image above).

Stiff creases

The team’s mathematical description is based on several parameters, including the ratio of the width of the ring being folded to the radius of the ring. The angle of the crease is also important, along with the “stiffness” of the crease – the latter being a measure of how difficult it is to change the angle of the fold. Another important parameter is the stiffness of the material itself – a measure of how difficult it is to bend the sheet from which the ring is made of.

The team derived an equation for the total energy of a creased ring in terms of these parameters and then calculated the energy using several analytical and numerical techniques. In addition to the angle of the crease, the results suggest that two ratios play an important role in the shape of the 3D structure – the ratio of width of the ring to its radius and the ratio of the stiffness of the crease to the bending stiffness of the material.

When the ratio of the crease stiffness to the bending stiffness is relatively high, the angle of the crease will not change – and the structure will respond to the stresses by bending to create a 3D shape.

In the case of the relative width of the ring, the team found that the wider the ring the more rigid the 3D structure – something that Santangelo believes could be exploited to make strong, flexible yet lightweight 3D structures. The team also extended the model to describe rings with multiple creases, which results in more complicated 3D structures.

The research is described in Physical Review Letters.