A bizarre property of silicon could lead to a cheaper way of purifying this most useful of electronic materials. That is according to researchers at Massachusetts Institute of Technology (MIT) who have observed the effect of silicon melting when cooled – a process that results in the separation of silicon from some of its impurities.

This “retrograde melting” has been observed previously in several other materials and it can occur for more than one reason. In the case of silicon, the MIT team led by Steve Hudelson says that the effect results from the material becoming supersaturated when it is cooled. Hudelson’s team was able to track the process with X-ray fluorescence measurements taken at the Advanced Light Source (ALS) at Lawrence Berkeley National Laboratory in California.

The researchers took a sample of silicon deliberately contaminating with traces of copper, nickel and iron, and heated the material to 1000 °C – more than 400 °C below silicon’s melting temperature. Then, as they cooled the mixture below 900 °C, they observed the formation of tiny liquid droplets within the body comprising silicon and the three impurities. As the team continued to cool the material, the impurities became increasingly separated from the silicon within the droplets. Eventually the material became completely solid again once it dropped below a critical point known as its “eutectic temperature” – around 700 °C.

Little vacuum cleaners

The findings could be useful for the semiconductor manufacturing industry where one of the big challenges is to regulate mixtures of silicon and its impurities. “If you can create little liquid droplets inside a block of silicon, they serve like little vacuum cleaners to suck up impurities,” says Tonio Buonassasi, a member of the MIT team.

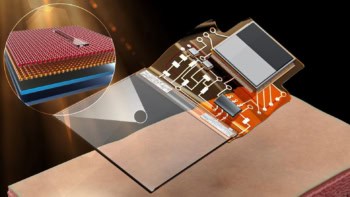

Also, many electronic applications – including solar cells – involve deliberately introducing impurities into silicon, so the findings could help to researchers to control the chemical interactions within these materials.

The results have just been published online in Advanced Materials.