Additive manufacturing, otherwise referred to as 3D printing, enables rapid and precise fabrication of multilayer and complex structures. The technique has been utilized in the field of biofabrication to manufacture tissues and organs for transplantation, therapies and disease modelling.

One of the key issues for biofabrication is developing a biomaterial that can provide a suitable environment for encapsulated cells, yet also have the properties of a printable biomaterial (bioink). A multinational research team has designed a set of physical and functional characteristics that can be applied to prospective bioinks to predict their printability and biological compatibility (Biofabrication 9044107).

Rheological properties

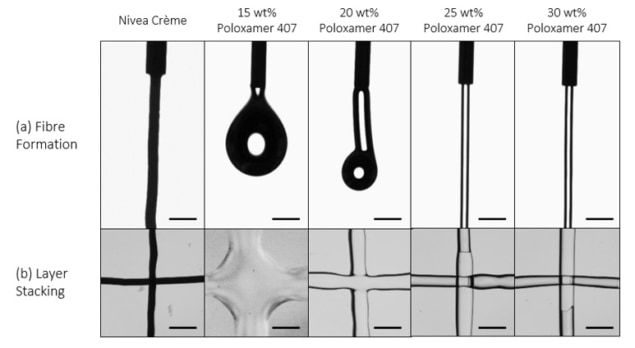

Rheology, the science of flow, is crucial to well-defined bioprinting, with bioink flow and gelation enabling printing and formation of a solid structure. The research team, headed up at Julius-Maximilians-Universitat Wurzburg, initially assessed bioink printability visually, for printing of defined fibres, rather than loose droplets, and its capability to be stacked into distinct layers.

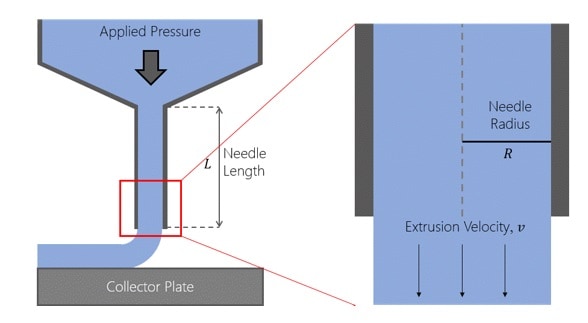

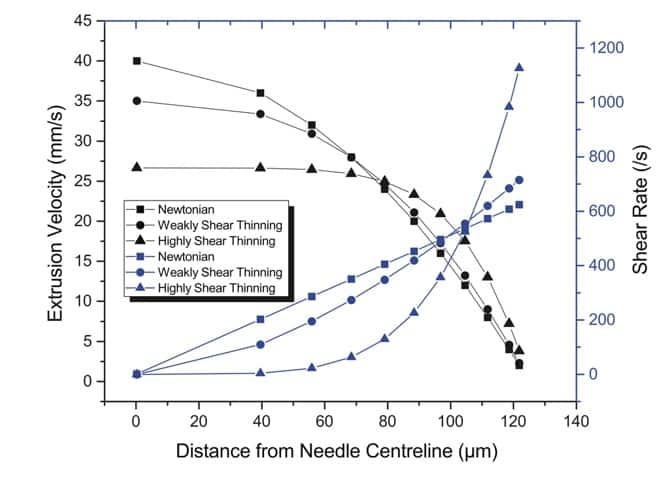

Next, they assessed the physical (also known as rheological) properties, which dictate bioink flow, shear thinning properties and speed of post-printing gelation. These data were collated by the authors to produce a “printing window”, in which printing pressure and other factors are optimal for bioprinting.

Cell health

An equally important characteristic for a bioink is the biological health of cells once encapsulated within the biomaterial. The researchers established this by measuring healthy cells versus dead cells, to determine how suitable the bioink is for housing cells post-printing.

It is also important to ensure that the printing process does not put too much physical stress on cells. The researchers established that cells on the outer region of a printed fibre exhibited higher rates of cell death, due to the higher levels of shear stress experienced during the printing process.

Bioinks checklist

The bioink screening established by the authors allows for the validation of a material for printing of a 3D tissue or organ construct. Implementation of such screens can speed up the process of selecting a suitable bioink for a chosen application, although further optimization may be needed to ensure that a bioink enables certain physiological functions; for example, the formation of blood vessels (vascularization) or growth of new synapses (neurogenesis) in brain tissue.

Overall, the introduction of these screening processes can lead to the implementation of a printing window that will accelerate the development of bioinks and bioprinting across the field of biofabrication. This will hopefully lead to exciting developments in the biofabrication of tissues and organs for disease modelling, therapies and transplantation.