A new passive radiative “cooling wood” that reflects infrared radiation could reduce the energy costs associated with cooling buildings by between 20 and 60%. The material, which is more than eight times stronger than natural wood, is made by removing the lignin from wood and then compressing the delignified structure.

“Buildings account for more than 40% of the total energy demand and 70% of electricity use in the US, leading to an annual energy bill of more than $430 billion,” explain Liangbing Hu of the University of Maryland and colleagues. “Heating and cooling accounts for roughly 48% of this energy use, making it the largest individual energy expense.”

Cooling a building is generally more difficult than heating it. Passive radiative cooling materials, which cool a structure by deflecting incoming solar radiation and dissipating heat with no external energy input, have come along in leaps and bounds in recent years, but these can be difficult to manufacture on a large scale.

Wood has been used in construction for thousands of years and has recently emerged as an important sustainable building material that could replace steel and concrete. Hu and colleagues engineered their cooling wood by completely removing the element that absorbs solar radiation, lignin, from it.

Cellulose nanofibres strongly emit light in the infrared

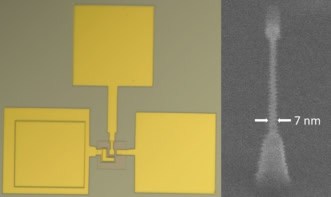

Scanning electron microscopy images reveal that the wood contains cellulose nanofibres that do not absorb in the visible part of the electromagnetic spectrum. These multiscale fibres and the channels between them in fact act as random and disordered light scattering elements at all visible wavelengths. At the same time, the molecular vibration and stretching of cellulose molecules in the wood strongly emit light in the infrared at all angles from the surface of the material in the so-called first and second atmospheric transparency windows of 8 to 13 μm and 16 to 25 μm respectively. The result is that the heat flux emitted by the material is greater than the absorbed solar irradiance, which leads to passive cooling.

The researchers measured the Fourier transform infrared absorbance of their wood and found that the strong infrared emission at wavelengths of 8 to 13 μm comes mainly from the complex infrared emission of OH groups on the cellulose together with C-H, C-O and C-O-C stretching vibrations between 770 and 1250 cm-1. The strongest IR absorbance by OH and C-O centres is at around 1050 cm-1 (9 μm).

Good radiative cooling powers

The team, which includes scientists from the University of Colorado Boulder, the University of California Meced and Huazhong University of Science and Technology in Wuhan, tested the performance of the wood in Cave Creek, Arizona, using continuous thermal measurements on samples measuring 200 x 200 mm placed 12 metres above ground (to avoid heat conduction from the ground to the samples).

The researchers found that the wood had radiative cooling powers of 63 and 16 W/m2 during the night and daytime (between 11 o’clock in the morning to 2 pm) respectively. This leads to an average cooling power of 53 W/m2 over the 24-hour period.

Continuous sub-ambient cooling

“Our wood is capable of continuous sub-ambient cooling – that is, keep its surface cooler than ambient air temperature,” says Hu. “It also features an exceptional tensile mechanical strength of as high as 404.3 MPa and a toughness of 3.7 MJ/m3, values that are, respectively, eight and 10 times tougher higher than those of natural wood.”

The material also has a specific tensile strength (the ratio of mechanical strength to weight) of 334.2 MPa cm3, which is higher than that of most structural materials, including Fe-Mn, Al-C steel, magnesium, aluminium alloys and titanium alloys, he adds. It requires no energy input either and could thus be a sustainable material for improving the energy efficiency of buildings.

Modelling potential energy savings

The researchers, reporting their work in Science 10.1126/science.aau9101, modelled the potential energy savings of using their cooling wood on the exterior surfaces of buildings using the whole building energy simulation program EnergyPlus version 8 and parameters listed in their paper. This model accounts for a total heat balance on both the internal and external building enclosure surface, the heat transfer through the building enclosures and heat sources and sinks, they explain.

The building models employed in this study are midrise apartments in 16 cities in the US and include both old (built before 1980) and new (built after 2004) buildings. The energy modelling process established a baseline energy consumption for these buildings and then recalculated this by supposing that the building materials had, in part, been replaced by the cooling wood.

We determined the total cooling energy-saving patterns for the selected 16 cities and the percent savings relative to the baseline and found that found that an average of ~35% and ~20% in cooling energy savings can be obtained for old and new midrise apartment buildings, respectively, say the researchers.

Bioinspired mechanical gradients make engineered wood

The energy savings that come from installing the cooling wood on the exterior surfaces of these buildings show that Austin (22.9 MJ/m2), Honolulu (28.2 MJ/m2), Las Vegas (21.1 MJ/m2), Atlanta (17.1 MJ/m2), and Phoenix (32.1 MJ/m2) would have the highest energy savings among the selected 16 cities. Phoenix had the highest because of its hot and dry climate.

“We conclude that the Southwest may be the area to benefit the most from this material to reduce energy consumption for cooling,” says Hu. “Indeed, UMD spinoff company Inventwood LLC in Maryland is now commercializing this technology,” he tells Physics World.