Flexible glass that does not shatter on impact could soon be made using insights from a study of a glass-like material made from aluminium oxide. Erkka Frankberg at Tampere University in Finland and colleagues have come to this conclusion after studying the molecular mechanisms the prevent cracks forming in the material.

Glass has lots of very useful properties including optical transparency, durability and low electrical conductivity. However, the inherent brittleness of the material has prevented it from finding a wider range of applications.

Glass is brittle because it no way to effectively dissipate mechanical energy when it is deformed by external forces. Instead, the energy accumulates around microscopic defects. This leads to localized concentrations of stress and eventually to the propagation of sharp cracks and shattering.

Blunter cracks

This weakness is particularly pronounced in traditional glasses made of silicates (silicon oxides), which form rigid tetrahedral structures that encourage the propagation of sharp cracks. In principle, brittleness in glass could be overcome by blunting the tips of cracks as they propagate – something that occurs in ductile materials. If achieved, this would give glass far higher mechanical strength, and make it less likely to fail because of defects.

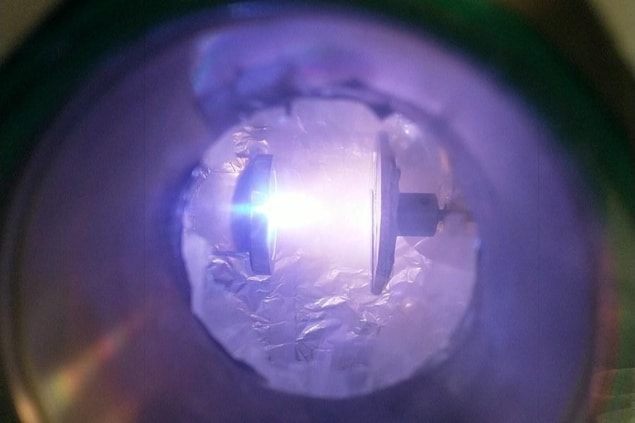

Frankberg’s team created a new type of glass from aluminium oxide (alumina) using a technique called pulsed laser deposition. This was a significant challenge in because the material normally occurs in a crystalline form, rather than in an amorphous glassy state. In contrast to silicates, amorphous alumina can deform irreversibly at room temperatures. Through a combination of transmission electron microscopy with molecular dynamics simulations, they explored the mechanisms by which this deformation occurs.

Alumina glass bends rather than breaking

The team discovered that molecular bonds in amorphous alumina are up to 25 times more likely to break and reform when distorted – compared to bonds in silicate glass. This allows mechanical stresses in the materials to relax. Furthermore, localized strain events within the material can accumulate into ductile flows instead of concentrated stresses, allowing blunter cracks to form. The team then showed that this “viscous creep” mechanism allows amorphous alumina to endure far higher strains without fracturing. Indeed, they were able to the materials elongate by up to 100% in the most extreme scenarios.

Despite the excitement surrounding their findings, Frankberg’s team acknowledges that they looked at idealized samples of amorphous alumina that were free from defects. This means that commercialized products incorporating the material are currently an unrealistic prospect. However, the researchers say that their results provide important guidelines for developing generalized strategies for tailoring the mechanical properties of oxide glasses.

The research is described in Science.