For most manufacturers, cracks are usually something to be avoided – and the semiconductor industry is no exception. But now engineers in South Korea have shown how initiating and then controlling the spread of nanometre-sized cracks can be used to create pre-designed patterns in a silicon wafer. They say that their approach offers a potentially faster and cheaper alternative to conventional lithography for the fabrication of integrated circuits.

Cracks can form when two materials with mismatching crystalline structures are placed on top of one another. Stress builds up at the interface between the materials, deforming the crystal structures and creating a crack that spreads throughout both materials if the deformity builds up enough potential energy to break atomic or molecular bonds. This can happen when a thin layer of silicon nitride is deposited on a silicon substrate, with cracks spreading uncontrollably through one or both of the layers.

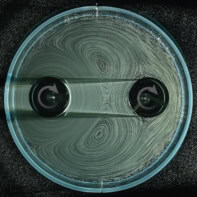

Koo Hyun Nam of the Ewha Womans University in Seoul and colleagues have controlled the formation of such cracks to create elaborate patterns within a silicon substrate. To do this they etched tiny structures at particular positions and with specific orientations within 0.5 mm-thick silicon wafers. The idea was that these “micro-notches” would concentrate the stress resulting from the deposition of a thin film of silicon nitride on the substrate. They also carved out step-like structures within the substrate to halt the spread of cracks or to isolate certain regions of the wafer from cracks.

Wavy cracks

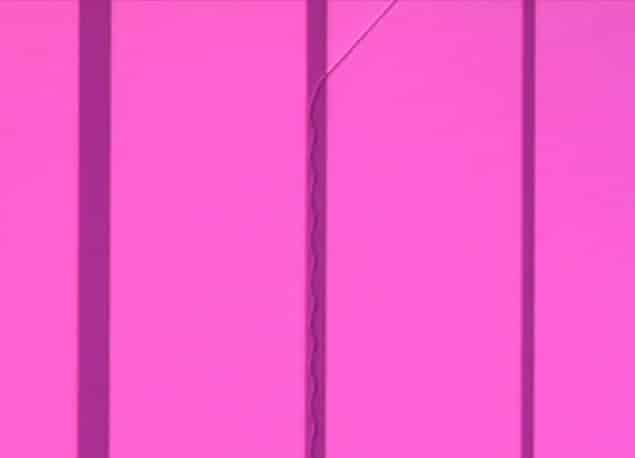

Using chemical vapour deposition to lay down the silicon nitride, Nam and co-workers found that the cracks formed and propagated spontaneously. They were able to make the cracks either straight or wavy by changing the orientation of the crystal planes in the wafers as well as adjusting other parameters such as the temperature and pressure of the vapour. By laying down a film of silicon dioxide between the substrate and the silicon nitride they were able to generate a third shape – “stitch-like” cracks, which are straight cracks with short, parallel, angled branches.

The width of the cracks varied between about 10–120 nm, with the wavelike variety generally wider than the straight cracks. In addition, the researchers found that they could change the direction of a crack, causing it to “refract” much like a light wave passing into and then out of a block of glass, by separating only a part of the wafer and the silicon nitride with the silicon-dioxide film. Where there was no silicon dioxide, the crack penetrated more deeply into the silicon substrate and aligned itself more closely with the substrate’s atomic planes, whereas this alignment was weaker where there was silicon dioxide, causing the crack to change direction in this region.

Writing in Nature, Nam’s team says that this method of controlled cracking could offer a faster and cheaper alternative to conventional lithography for microchip fabrication. In an accompanying article, Antonio Pons of the Polytechnic University of Catalonia in Barcelona, Spain, agrees. He says that lithography, which allows patterns to be etched in silicon using a mask created via beams of light, electrons or ions, is often complex, expensive and time-consuming.

Hours, not weeks

Pons told physicsworld.com that the advantage of the new approach is that the time needed to form the pattern “is simply the time taken for the crack to propagate”, estimating that it should take only a few hours altogether to prepare the substrate, deposit the film and create the pattern, compared with the “days or weeks” needed using standard lithography. He admits, however, that he does not know how long it would take to make the micro-notches and other features. He also says it remains unclear how closely the cracks can be positioned to one another, something, he points out, “that is crucial when making small structures”.

But Pons believes that the new technique should also find applications beyond the semiconductor industry. One possibility, he says, is making microfluidic devices. These are networks of tiny channels within which fluids, containing molecules such as DNA, can be manipulated for study. He also wonders whether it might prove useful at larger scales, perhaps allowing buildings in earthquake zones to fracture more safely. “The answer to that is not necessarily yes,” he says. “Scale is very important, and we would be going from atomic-level interactions to the size of a house. But maybe this work will inspire people in other fields.”

Zhenan Bao, a chemist at Stanford University in the US, says that the strength of the latest work is in showing the formation of controlled cracking, pointing out that other groups have previously used cracks to create nanoscale patterns, but that they were not able to carefully control where the cracks formed. Bao cautions, however, that such controlled cracking would only be possible with certain combinations of materials, which may mean the technique has more limited appeal than standard lithography. “It would be nice to see a demonstration of this method for device application,” she adds.