By Hamish Johnston

Yesterday I was up in Telford – birthplace of the industrial revolution – for Photonex and the Vacuum Expo.

It’s the first time that a vacuum event has been run alongside Photonex, which not surprisingly is focused on photonics.

Physics World is a media sponsor of the Vacuum Expo – which wraps up today – and we had a booth at the exhibition.

My first stop on the exhibition floor was the FLIR booth, where I met with Jon Chicken. Jon was showing off the firm’s latest infrared imaging systems – which you can see him demonstrating in the photo above.

Jon was very keen to talk about FLIR’s “super framing” technology – or as he prefers to call it “multiple integration time” or just “multi-IT”. The technique involves processing a stream of IR images, each with a different integration time. The technique is good for looking at subjects in which the local temperature varies over a wide range.

So, what are some exciting applications of this latest IR technology? It could be used, for example, to measure the temperature inside a fusion reactor. Indeed, Jon told me that the firm’s systems will be going into the ITER demonstration reactor that is currently being built in the south of France.

Continuing in the theme of fusion, my next stop was a booth promoting the laser fusion activities of the UK’s Rutherford Appleton Laboratory and the proposed HiPER laser fusion programme.

RAL’s Ceri Brenner (right) was there to explain how HiPER is expected to use powerful lasers to implode a tiny pellet containing deuterium and tritium – creating a dense hot plasma in which nuclear fusion can occur. If all goes to plan, 10 pellets per second will be ignited at HiPER, which will result in a net production of energy – which could someday power your toaster!

Ceri is also interested in developing another practical application of laser-plasma interactions – tabletop particle accelerators. In particular, she’s looking at how protons can be accelerated to tens and maybe hundreds of MeV using a laser. The idea is that an intense pulse of laser light separates electrons from ions in a plasma creating an extremely high electric field that can be used to accelerate changed particles such as protons.

Such a proton source could be very handy for medical therapies based on heavy charged particles. There are two challenges, however, that must be overcome. Current sources can only accelerate protons up to about 65 MeV. These could be used for treating the eye, but not for other applications, which need protons at 150–200 MeV. The other challenge is that the protons are produced over a wide energy range, but proton therapies are only effective if the particles have a very narrow energy distribution.

Laser accelerators are just one example of a technology that was first developed by academics and is now well on the road to commercialization. One person who has been down that road many a time is Tiju Joseph (right), who splits his time between the UK’s National Physical Laboratory (NPL) and the University of Surrey.

Joseph is a “technology translator” who tries to encourage academics to think about the commercial potential of their research. But it’s not about sitting back and waiting for eager scientists to approach him with ideas – he figures only about 5% of successful ventures start that way. Instead, it’s all about Joseph learning about what a scientist has done over the past ten years and then sitting down with the researcher and discussing avenues of commercialization.

You might think that the goal is always a spin-out company that is sold by the university once it has been established. According to Joseph, this is passé because it is just too cumbersome. Today, the goal seems to be to license the technology to an established firm with the ability to develop it rapidly.

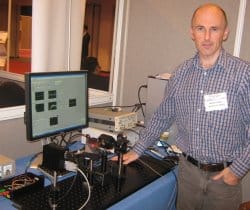

Now, it wouldn’t be a photonics show without a laser and a few optical components, and that’s just what the University of Limerick’s Michael Connelly brought to Telford. Michael (right) was showing off his “low-cost laser Doppler vibrometer”, which is a way of measuring vibration by firing a laser at the object of interest and comparing the reflected beam with a reference beam in an interferometer.

Also working on a practical application of photonics is Shijie Liang of the University of Manchester, who told me about her work on creating “long-period gratings” within polymer fibres. Such gratings cause light at certain wavelengths to be absorbed by the fibre cladding – a process that is very sensitive to environmental factors such as the temperature of the fibre. As such, long-period gratings can be used as temperature or other probes.

While such gratings have been made in silicon, such fibres tend to be very fragile, which is why Liang is keen on much more flexible polymers.

With all those laser beams whizzing around, I felt I needed a pair of safety glasses. Fortunately Paul Tozer of Lasermet had a few fetching pairs on display that might even tempt Bono (above). The UK-based firm supplies a wide range of laser safety equipment and Paul talked about the company’s business, including the refitting of laser labs in the UK and beyond.