Scientists in the Netherlands have used a micromachined "fountain pen" to write and etch sub-micron patterns on a surface with molecular "ink". The new device developed by Miko Elwenspoek and colleagues at the University of Twente is based on an atomic force microscope (S Deladi at al. 2004 Appl. Phys. Lett. 85 5361).

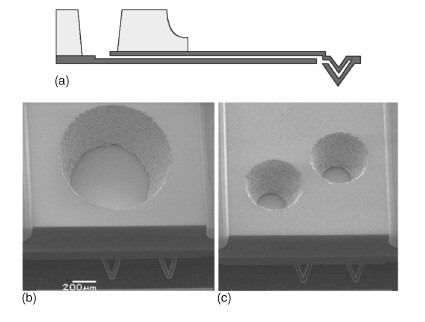

Atomic force microscopes (AFMs) were originally designed to study surfaces but they are now routinely used for surface modification as well. In the new device built by Elwenspoek and colleagues, the ink flows from a reservoir through a channel in the cantilever that supports the tip and on to the tip itself (figure 1).

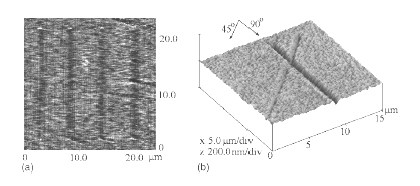

Using 1-octodecanethiol as the ink, the Twente team drew lines just 0.5 microns wide on a gold substrate. The ink reacts with the gold to produce a stable monolayer structure on the substrate. In separate experiments with a commercial etchant, the tip was able to etch trenches just 0.3 microns wide and 14 nanometres deep in a chromium surface (figure 2).

The team used the technique to draw and etch straight lines but any pattern could, in principle, be created. It might also be possible to reduce the width of the lines and the trenches further by sharpening the AFM tip.

Elwenspoek and co-workers say their device is an improvement on existing AFM-based surface-modification techniques, such as “dip-pen lithography”, because it can hold more ink and the flow of this ink can be better controlled. Moreover, by creating a local environment around the tip, the operation of the device is not affected by humidity in the atmosphere.

“The fountain pen will extend the possibilities of probe-based nanolithography,” team member Szabolcs Deladi told PhysicsWeb. “It could be used in new nanofabrication techniques like local electrochemical etching and deposition to create 3D nanostructures.”

The Twente team now plans to do further work on the device itself and also on the ink, including improvements to its viscosity and wetting properties.