Dutch researchers have discovered a way of creating polymers in liquid carbon dioxide using ultrasound. Martijn Kuijpers and colleagues at the Eindhoven University of Technology used high intensity sound waves to produce poly-methylmethacrylate from a mixture of carbon dioxide and methyl methacrylate monomers at high pressure. They believe that this method could reduce the use of toxic organic solvents currently used in polymer processing (MWA Kuijpers et al. 2002 Science 298 1969)

One of the most common ways of making polymers is from vinyl monomers — small molecules containing carbon-carbon double bonds — in a process called free radical polymerization. At present, the “initiators” used in such reactions are organic peroxides, which are hazardous and environmentally unfriendly. Now, Kuijpers and co-workers propose using ultrasound in a technique that could reduce the use of such chemicals.

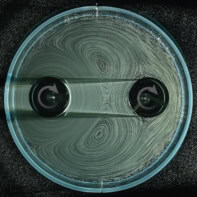

Ultrasound waves cause bubbles to form in liquid carbon dioxide. These bubbles — a few tens of microns in size — then expand and collapse violently. This “cavitation” generates tiny pockets of very high temperature and pressure, which can then create excited states in a molecule, break chemical bonds and form radicals in the polymerization process.

To initiate the growth of a cavitation bubble, a pressure above a certain threshold must be applied. However, pressurizing a liquid raises this threshold and prevents bubbles from forming. The advantage of liquid carbon dioxide is that it has high vapour pressure, which effectively counteracts the hydrostatic pressure – the pressure needed to keep the carbon dioxide in its liquid state. This means that the threshold pressure is decreased and bubbles can form.

When liquid carbon dioxide is mixed with the polymer it acts as an “antisolvent” that makes the polymer insoluble in the high-pressure liquid gas. In this way, the polymer precipitates out of solution without the need for a solvent. Cavitation also enables the polymer chain to be broken at specific sites so that a desired molecular weight of polymer can be obtained. Another advantage of this technique is that turning off the electrical supply can stop a polymerisation reaction that proceeds too quickly. This control is not possible with any other methods currently used.