The semiconductor industry is an economic powerhouse, but it is not without its challenges. As well as shortages of new semiconductor chips, it increasingly faces an oversupply of counterfeit ones. The spread of these imitations poses real dangers for the many sectors that rely on computer chips, including aviation, finance, communications, artificial intelligence and quantum technologies.

Researchers at Purdue University in the US have now combined artificial intelligence (AI) and photonics technology to develop a robust new method for detecting counterfeit chips. The new method could reduce the risks of unwanted surveillance, chip failure and theft within the $500 bn global semiconductor industry by reining in the market for fake chips, which is estimated at $75 bn.

The main way of detecting counterfeit semiconductor chips relies on “baking” security tags into chips or their packaging. Such tags work using technologies such as physical unclonable functions made from media such as arrays of metallic nanomaterials. These structures can be engineered to scatter light strongly in specific patterns that can be detected and used as a “fingerprint” for the tagged chip.

The problem is that these security structures are not tamper-proof. They can degrade naturally – for example, if temperatures get too high. If they are printed on packaging, they can also be rubbed off, either accidentally or intentionally.

Embedded gold nanoparticles

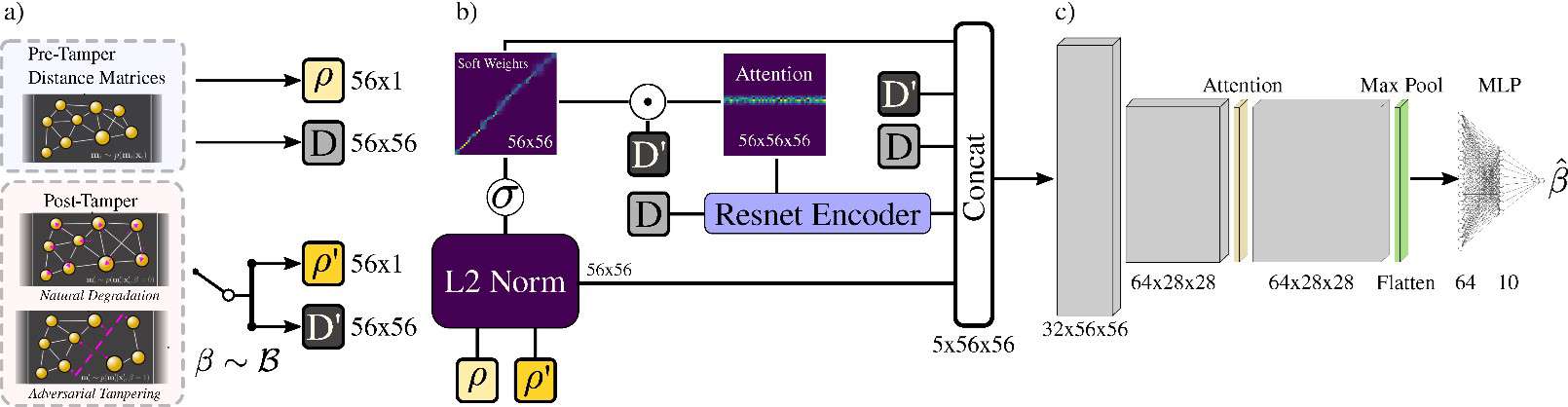

The Purdue researchers developed an alternative optical anti-counterfeiting technique for semiconductor devices based on identifying modifications in the patterns of light scattered off nanoparticle arrays embedded in chips or chip packaging. Their approach, which they call residual attention-based processing of tampering response (RAPTOR), relies on analysing the light scattered before and after an array has degraded naturally or been tampered with.

To make the technique work, a team led by electrical and computer engineer Alexander Kildishev embedded gold nanoparticles in the packaging of a packet of semiconductor chips. The team then took several dark-field microscope images of random places on the packaging to record the nanoparticle scattering patterns. This made it possible to produce high-contrast images even though the samples being imaged are transparent to light and provide little to no light absorption contrast. The team then stored these measurements for later authentication.

“If someone then tries to swap the chip, they not only have to embed the gold nanoparticles, but they also have to place them all in the original locations,” Kildishev explains.

The role of artificial intelligence

To guard against false positives caused by natural abrasions disrupting the nanoparticles, or a malicious actor getting close to replacing the nanoparticles in the right way, the team trained an AI model to distinguish between natural degradation and malicious tampering. This was the biggest challenge, Kildishev tells Physics World. “It [the model] also had to identify possible adversarial nanoparticle filling to cover up a tampering attempt,” he says.

Writing in Advanced Photonics, the Purdue researchers show that RAPTOR outperforms current state-of-the-art counterfeit detection methods (known as the Hausdorff, Procrustes and average Hausdorff metrics) by 40.6%, 37.3%, and 6.4% respectively. The analysis process takes just 27 ms, and it can verify a pattern’s authenticity in 80 ms with nearly 98% accuracy.

New single-photon detector targets high-speed quantum communications

“We took on this study because we saw a need to improve chip authentication methods and we leveraged our expertise in AI and nanotechnology to do just this,” Kildishev says.

The Purdue researchers hope that other research groups will pick up on the possibilities of combining AI and photonics for the semiconductor industry. This would help advance deep-learning-based anti-counterfeiting methods, they say.

Looking forward, Kildishev and colleagues plan to improve their nanoparticle embedding process and streamline the authentication steps further. “We want to quickly convert our approach into an industry solution,” Kildishev says.