Researchers in China have adapted the interlocking structure of mortise-and-tenon joints – as used by woodworkers around the world since ancient times – to the design of nanoscale devices known as memristors. The new devices are far more uniform than previous such structures, and the researchers say they could be ideal for scientific computing applications.

The memory-resistor, or “memristor”, was described theoretically at the beginning of the 1970s, but the first practical version was not built until 2008. Unlike standard resistors, the resistance of a memristor changes depending on the current previously applied to it, hence the “memory” in its name. This means that a desired resistance can be programmed into the device and subsequently stored. Importantly, the remembered value of the resistive state persists even when the power is switched off.

Thanks to numerous technical advances since 2008, memristors can now be integrated onto chips in large numbers. They are also capable of processing large amounts of data in parallel, meaning they could be ideal for emerging “in-memory” computing technologies that require calculations known as large-scale matrix-vector multiplications (MVMs). Many such calculations involve solving partial differential equations (PDEs), which are used to model complex behaviour in fields such as weather forecasting, fluid dynamics and astrophysics, to name but a few.

One remaining hurdle, however, is that it is hard to make memristors with uniform characteristics. The electronic properties of devices containing multiple memristors can therefore vary considerably, which adversely affects the computational accuracy of large-scale arrays.

Inspiration from an ancient technique

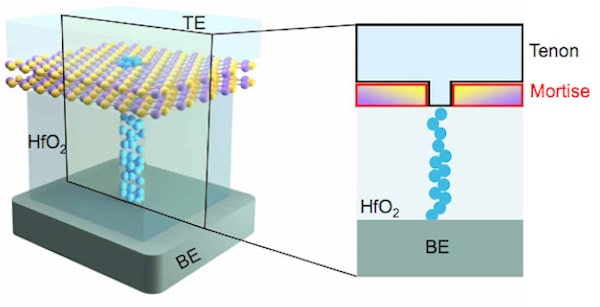

Physicists co-led by Shi-Jun Liang and Feng Miao of Nanjing University’s School of Physics say they have now overcome this problem by designing a memristor that uses a mortise-tenon-shaped (MTS) architecture. Humans have been using these strong and stable structures in wooden furniture for thousands of years, with one of the earliest examples dating back to the Hemudu culture in China 7 000 years ago.

Liang, Miao and colleagues created the mortise part of their structure by using plasma etching to create a hole within a nanosized-layer of hexagonal boron nitride (h-BN). They then constructed a tenon in a top electrode made of tantalum (Ta) that precisely matches the mortise. This ensures that this electrode directly contacts the device’s switching layer (which is made from HfO2) only in the designated region. A bottom electrode completes the device.

The new architecture ensures highly uniform switching within the designated mortise-and-tenon region, resulting in a localized path for electronic conduction. “The result is a memristor with exceptional fundamental properties across three key metrics,” Miao tells Physics World. “These are: high endurance (over more than 109 cycles); long-term and stable memory retention (of over 104 s), and a fast switching speed of around 4.2 ns.”

Memristors make versatile artificial synapses for neuromorphic computing

The cycle-to-cycle variation of the low-resistance state (LRS) can also be reduced from 30.3% for a traditional memristor to 2.5% for the MTS architecture and the high-resistance state (HRS) from 62.4 to 27.2%.

To test their device, the researchers built a PDE solver with it. They found that their new MTS memristor could solve the Poisson equation five times faster than a conventional memristor based on HfO2 without h-BN.

The new technique, which is detailed in Science Advances, is a promising strategy for developing high-uniformity memristors, and could pave the way for high-accuracy, energy-efficient scientific computing platforms, Liang claims. “We are now looking to develop large-scale integration of our MTS device and make a prototype system,” he says.