Two teams of researchers in the US have taken important steps towards the creation of commercially viable “artificial leaf” – a hypothetical device that can turn sunlight into electrical energy or fuel by mimicking some aspects of photosynthesis.

Earlier this year, the chemist Daniel Nocera at the Massachusetts Institute of Technology (MIT) announced artificial-leaf prototypes at the annual meeting of the American Chemical Society in California. Now, working with two different teams of researchers, he has published two papers on different devices that represent progress towards effective and commercially viable versions of the artificial leaf.

Here comes the Sun

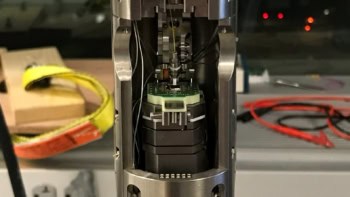

Both teams made their devices from silicon wafers that are coated with catalytic metals and protective layers. The prototype solar cells are about the size of a credit card and can capture sunlight and then use the energy to split water into its constituent oxygen and hydrogen. This is different to conventional photovoltaic cells, which convert light directly into electricity. With these new devices, the ultimate plan is to recombine the two gases in an integrated fuel cell, thus converting the chemical energy to electrical energy. Producing fuel rather than electricity has the advantage that the fuel can be easily stored until it is needed.

Both artificial leaves use a silicon n–p junction: a bilayer of n-type and p-type silicon. An incident photon is absorbed to create an electron–hole pair in the semiconductor. The electrons migrate to the n-side and the holes to the p-side. The holes then drive the splitting of water in a process mediated by the outermost layer of the cell, which is a photocatalyst. Unlike some of the exotic photocatalysts used in earlier devices, the catalyst in these new devices are made of cobalt phosphate, which is an abundant and cheap material.

The main challenge in creating both devices was how to prevent the silicon from reacting with the water. The two teams took different approaches to the problem. One group led by electrical engineer Vladimir Bulovic used the catalyst itself as a protective layer, binding a thin film of pure cobalt firmly to the silicon before converting it to the phosphate form. The other team, led by mechanical engineer Tonio Buonassisi, used a thin film of conductive indium tin oxide in front of the p-type silicon as the protective layer.

Bubbles needed

Buonassisi and colleagues connected two of their cells in series and managed to split water with a solar-to-oxygen conversion efficiency of 0.25%. While this does not sound like much, the efficiency of photosynthesis is only a few per cent. However, the cells make hydrogen ions, and turning this into gas could add considerable cost to the device. “Platinum electrodes are good catalysts for reducing hydrogen ions to hydrogen gas”, says Devens Gust of Arizona State University, who was not involved in the research. “However, the rarity of platinum limits its usefulness.”

Gust describes the MIT work as “very important in that it demonstrates a workable, inexpensive water-oxidation catalyst”. However, he says that the technology is entering a crowded market, pointing out that there is already a production technology for solar fuel that is “pretty much ready to go now”. This system uses photovoltaic cells coupled to an electrolyzer that splits water into oxygen and hydrogen. “Electrolyzer efficiencies can be as high as 70–80%, and currently available photovoltaic efficiencies are as high as 15–20%”, he points out. “None of the artificial photosynthetic systems can compete with this at the moment.”

The MIT technology must also compete with other water-splitting systems based on silicon solar cells coated with photocatalysts. These have been in development since at least 1998 and some have reached solar-to-hydrogen conversion efficiencies of 7% or better.

“Challenges remain”

One of these cells was developed at California Institute of Technology by Nathan Lewis and Harry Atwater. Atwater told physicsworld.com that “Nocera’s work is interesting, but many challenges remain.” It is not clear, for example, whether the catalyst and devices remain stable beyond the few days of operation for which they have so far been tested. Atwater also thinks there is room for improvement in the materials themselves.

Gust agrees, pointing out that while cobalt and other catalysts based on common materials are promising, researchers have yet to develop an inexpensive catalyst that works near the thermodynamic potential for water oxidation/reduction. This property would help to optimize the performance of an artificial-leaf system. Nocera hopes to have a fully working device within about three years, and he has formed a company called SunCatalytix to develop it.

The work by Bulovic’s group is published in Energy & Environmental Science, while the research by Buonassisi’s group is outlined in Proceedings of the National Academy of Sciences USA.